B-11

OPERATION

FLEXTEC

®

650x

Arc Link

This weld mode is intended to unlock basic non-synergic and

synergic modes intended for use with compatible ArcLink wire

feeders. All of the Flextec

®

650x user interface controls are

disabled in this mode and controlling the power source is accom-

plished from the wire feeder user interface.

Hot Start

– Not used for this welding process.

Arc Control

– Not used for this welding process.

Weld Terminals On/Remote

•

Not used for this welding process.

Amperage Display

– This display will display three dashed lines

when the machine is in the idle state. This indicates that

amperage is not settable in this weld mode. While output is

enabled, the actual welding amperage will be displayed. After

welding, the meter holds the actual amperage value for 5

seconds. Output adjustment while in the "hold" period results in

the "prior to operation" characteristics stated above. The displays

blink indicating that the machine is in the "Hold" period.

Voltage Display

– This display will display the pre-set welding

voltage when the machine is in the idle state. After welding, the

meter holds the actual voltage value for 5 seconds. Output

adjustment while in the "hold" period results in the "prior to

operation" characteristics stated above. The displays blink

indicating that the machine is in the "Hold" period.

Output Control Local/Remote

– Not used for this welding process

Output Control Dial

•

Not used for this welding process.

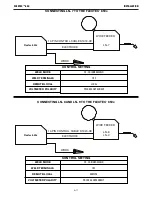

CrossLinc™

CrossLinc™ is a new welding system communication technology.

When using a CrossLinc™ enabled power source such as the

Flextec

®

650x and a CrossLinc™ enabled wire feeder such as the

LN-25X, welding voltage can be controlled remotely without the

use of an additional control cable.

The digital meters on the LN-25X will show the pre-set values for

wire feed speed and voltage prior to welding. During welding, the

meters will show actual current and voltage present at the wire

feeder. After welding the meters will then flash the last welding

current and voltage that was present during welding for 10-

seconds after welding. If WFS or voltage is adjusted during this 10

second period, the meters will go back to the pre-set value.

•

When a LN-25X enabled feeder is connected with the Flextec

®

650x using the standard weld power cable and the LN-25X

sense lead is attached to the work piece, the CrossLinc™

light will automatically illuminate on both the Flextec

®

650x

and the LN-25X. No additional pairing of the machine to the

feeder is needed. This light indicates the CrossLinc

connection is active and that control of the

Flextec

®

650x voltage can be made at the LN-25X feeder.

•

The Flextec

®

650x Weld Terminals On/Remote toggle should

be set to 'ON'. This powers the weld terminals for an across-

the-arc LN-25X wire feeder.

•

The Flextec

®

650x Output Control Local/Remote switch is

ignored once a CrossLinc peripheral is detected by the power

source.