A-9

INSTALLATION

FLEXTEC

TM

650

LN-10,DH-10 CONTROL SWITCH SETUP

Initial set up of the LN-10, DH-10 control for the system

components being used and for general operator preferences

is done using a pair of 8-pole DIP switches located inside the

LN-10, DH-10 control box.

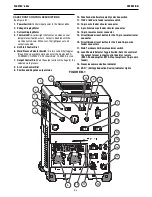

Setup DIP Switch Access

1) Shut off the input power to the LN-10, DH-10 control by

turning off the power at the welding power source it is

connected to.

2) Remove the two screws on the top of the LN-10, DH-10

control box door and swing the door down to open.

3) Locate the two 8-pole DIP switches, near the top left

corner of the LN-10, DH-10 Control P.C. board, labeled

S1 and S2.

4) Switch settings are only programmed during input

power-up restoration.

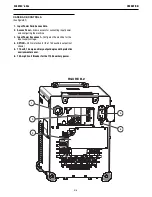

Setting the DIP Switches

The DIP switches are each labeled with an “ON” arrow

showing the on direction for each of the 8 individual switches

in each DIP switch (S1 and S2). The functions of these

switches are also labeled and set as described below:

Pwr Sources

S1

ON

S1

1 2 3 4 5 6 7 8

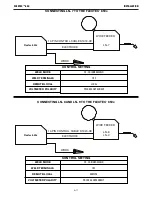

CONNECTING LN-10 AND DH-10 TO THE FLEXTEC

®

650x

CONTROL SETTING

14-PIN CONTROL CABLE K1501-XX

ELECTRODE

WIRE FEEDER

LN-10

DH-10

WORK

Flextec 650x

WELD MODE

WELD TERMINALS

REMOTE/LOCAL

VOLTMETER POLARITY

CV, CV-INNERSHIELD

OFF

REMOTE

PROCESS DEPENDENT