B-7

OPERATION

2.

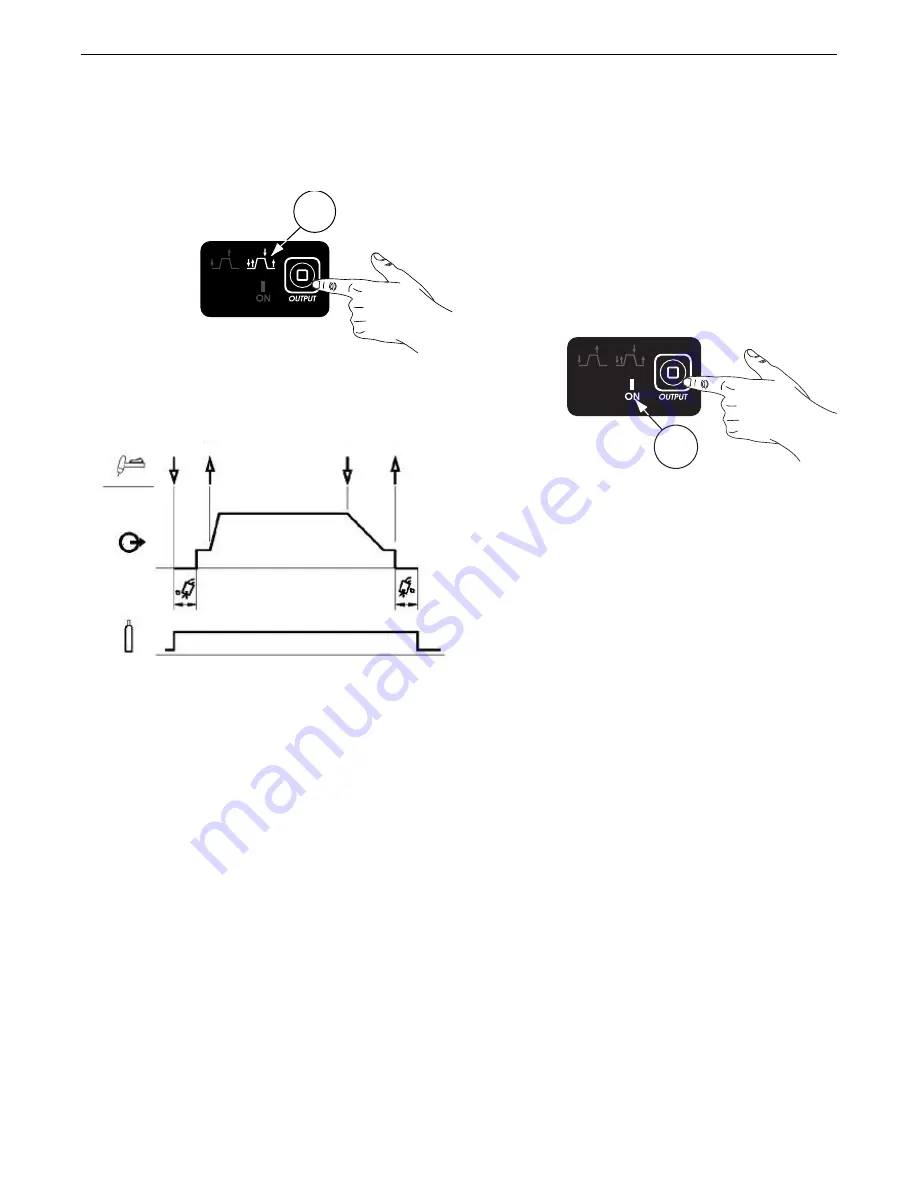

4-Step

(See Figure B.9) – With 4-step trigger mode and a TIG

welding mode selected, the following weld sequence will occur. In

4-step, all sequencer functions should be set. If a standard foot

amptrol is connected, only its trigger input is functional and the

remote output control will be disabled

4-Step Functionality

(See Figure B.10)

A. Press and hold the TIG torch trigger to start the

sequence. The machine will open the gas valve to

start the flow of shielding gas according to the set

pre-flow time. After the pre-flow, the output of the

machine is turned ON. The arc is started according

to the selected weld mode and the specified starting

current. The starting current will be held until the

torch trigger is released.

B. Releasing the trigger starts the initial slope function.

The output current will be increased at a rate

dependent on the specified initial slope time, until the

operating amperage is reached.

If the torch trigger is pushed during the upslope

time, the arc will immediately shut off and output will

be switched OFF.

C. When the main weld is complete, push and hold the

torch trigger to start the final down slope. The

machine will decrease the output current at a rate

determined by the specified final slope time, until the

finishing current is reached.

D. The finished current will be maintained for as long as

the torch trigger is held. Upon releasing the torch

trigger, output will be switched OFF and the post

flow time will start.

3.

Output On

-This function is designed to be used when

TIG welding without the use of an arc-start controller.

If “ON” is selected, the machine’s output terminals are

fully energized. Operator touches tungsten initiating

the starting process. Once the tungsten is lifted from

the work piece the amperage will proceed to welding

amperage. Output “ON” is always illuminated when

STICK welding.

(See Figure B.11)

ASPECT™ 375

(1)

(A)

(C)

(D)

(B)

A

2

3

FIGURE B.9

FIGURE B.11

FIGURE B.10