E-2

TROUBLE SHOOTING

Observe all Safety Guidelines detailed throughout this manual

If for any reason you do not understand the test procedures or are unable to perform the tests/repairs safely, contact your

Local Lincoln Authorized Field Service Facility

for technical troubleshooting assistance before you proceed.

ASPECT™ 375

CAUTION

Cycle power to clear the

fault. If problem persists,

contact Lincoln Authorized

Service Facility.

Cycle power to clear the

fault. If problem persists,

contact Lincoln Authorized

Service Facility.

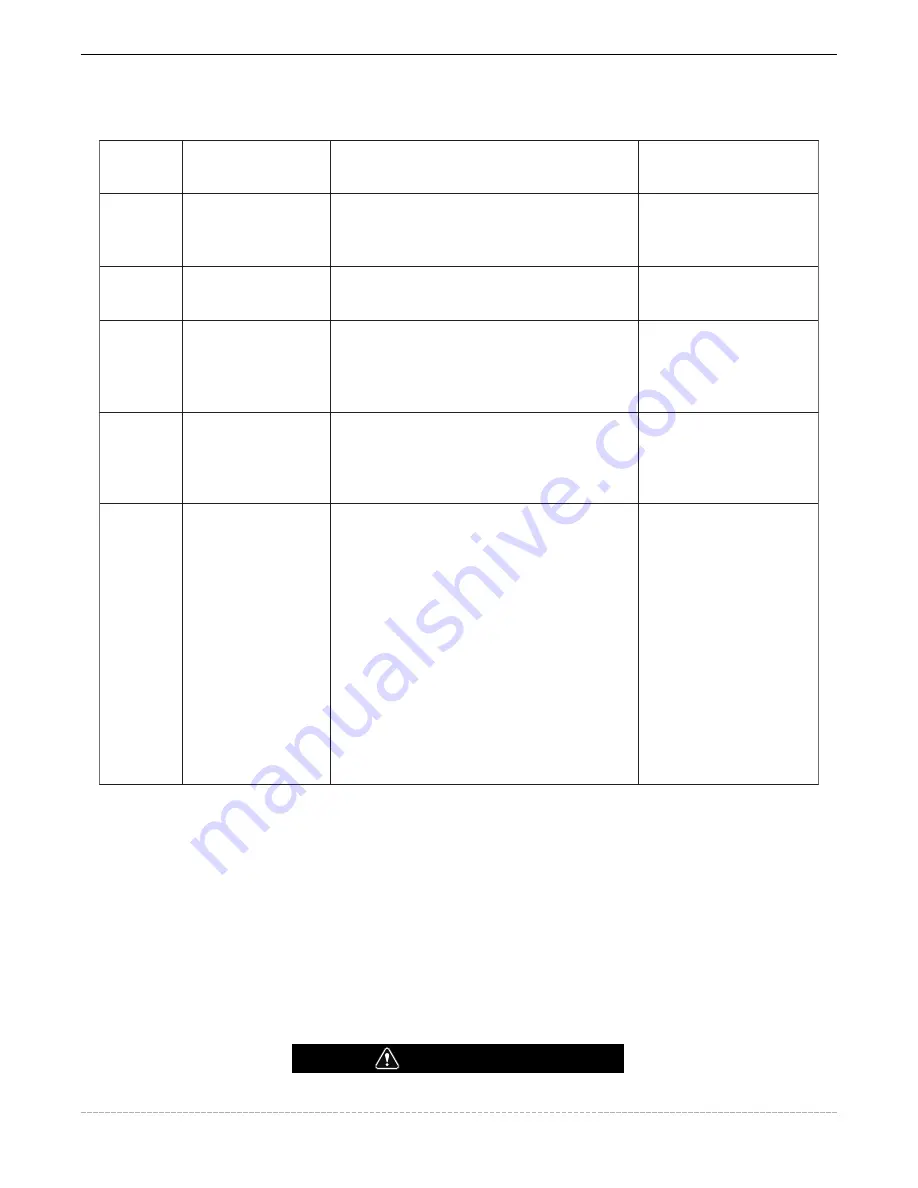

ERROR CODE LIST

CODE

DESCRIPTION

POSSIBLE CAUSE

CORRECTIVE

ACTION

01

Low input

Input voltage is lower than 200V or

drops below 200V under load

Check input voltage,

cable size, and fuse

size.

02

High input

Check input voltage.

05

AC switch

overload

Output overload

06

Inverter Under

Voltage Lock Out

In15V supply is too low

11

Water Cooler

Fault

Cooler is not plugged in to 115V receptacle,

insufficient coolant in cooler, TIG Torch is

undersized (amperage capacity) for application,

blown fuse, or faulty flow sensor inside cooler.

Input voltage is higher than 600V or

spikes above 600V under load

Initial Corrective Mea-

sures:

Check Cooler Connections,

Fill Cooler with additional

Low Conductivity Coolant

(KP4159-1), Replace with

higher amperage capacity

TIG Torch. Replace 3A

fuse. Depress Flow Sensor

Off button to remove error

code.

Secondary Corrective

Measures:

Service cooler