LIGHT PROGRESS

DIRECT-H-K [eng]

gen-2021

Pag. 8/16

WARNING!!!

To avoid exposition to UV-C rays please provide a total shielding of the modules, or automatic turning OFF disposals at

the entry doors in the environment treated. There must be no direct irradiation of the personnel.

To shield the devices you can use materials with opaque surfaces such as stainless steel or aluminium, but also trans-

parent materials such as glass or Lexan

®

; to have further information please contact us.

To improve safety we suggest you to add light signs or signboards to report the potential danger.

Remeber to switch on the device ONLY IF there is a concrete shield and no accidental ex-

position to the rays by the personnel.

SCHEDULING

Provide electric power to the device. The UV lampwill turn on. Remember not to expose people to UV-C rays irradia-

tion.

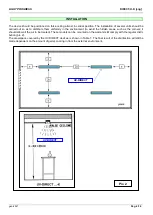

ELECTRICAL CONNECTIONS

We suggest you to let a qualified electrician to install this

device, following these instructions and the electrical

scheme, and following the CEI norms.

Make sure that the device will be installed where it will fit

with the existing environmental conditions. Before con-

necting the device to the electrical line, make sure that the

labelled data on the device are the same as the ones of

the electrical line; we remind you that the electrical supply

power of this device is 220-240V, 50/60Hz.

Make sure that the electrical system is suitable to provide

the supply current required by the device (please read the

label).

The connection to the electrical line needs a multipolar

switch.

The connection to the electrical line must be made by the

supplied cable 3 x 1 mm

2

.

The use of screws, nuts, or other means, is necessary to

connect the device to the electrical line.

We suggest the use of counters to know exactly the life of

UV lamps and to remember when replace them.

Protect the power supply cable from high temperature,

sharp corners, water, oils.