8 | EN

Copyright © Liberty Pumps, Inc. 2021 All rights reserved.

5647000M

Discharge

Make all discharge connections. A check valve is required to

prevent the backflow of liquid after each pumping cycle. A gate

valve should follow the check valve to allow periodic cleaning of

the check valve or removal of the pump. The remainder of the

discharge line should be as short as possible with a minimum

number of turns to minimize friction head loss. Do not reduce the

discharge to below the pump outlet size. Larger pipe sizes may be

required to eliminate friction head loss over long runs. Contact

Liberty Pumps or other qualified person if questions arise

regarding proper pipe size and flow rates.

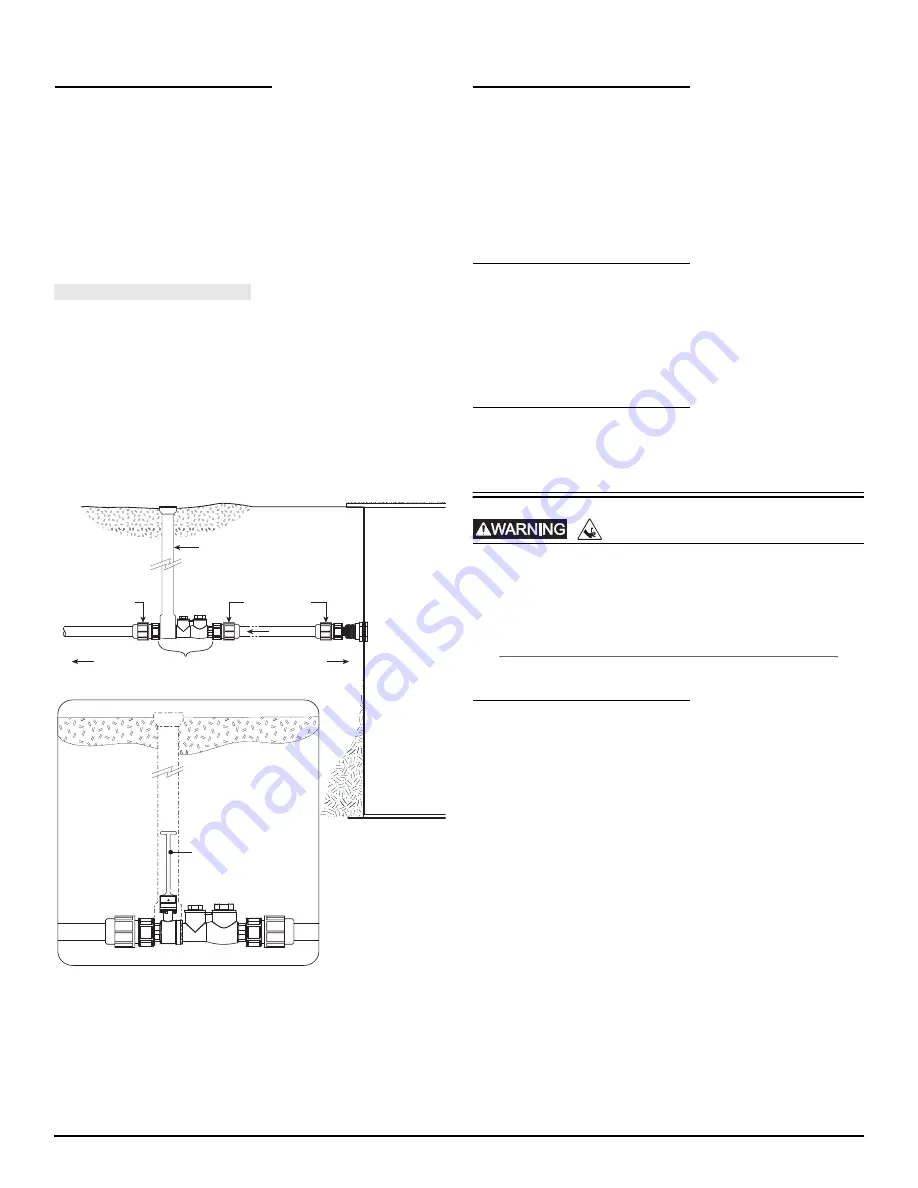

Pressure Sewer Applications

A redundant check valve assembly consisting of a curb stop and

check valve must be installed between the pump discharge and

the street main, as close to the public right-of-way as possible, on

all pressure (force main) sewer installations to protect from system

pressures. The curb stop valve is necessary to isolate the site from

the pressure sewer while the check valve provides redundant

protection against potentially detrimental backflow. All valves and

fittings should be rated for at least 200 PSI service. See Liberty

Pumps line of CSV-Series Curb Stop/Swing Check Valve

Assemblies and CK-Series Connection Kit.

Bulkhead

Connection

Pump Station

Compression

Adapter

Fitting

Curb Box

Compression

Adapter

Fitting

Valve Extension

Rod Shown

Curb Stop Valve/Swing

Check Valve Assembly

To Pump

To Main

Flow

Grade

Guide Rail System

If guide rails are used, refer to the separate instructions supplied

with the unit for proper installation and operation, making sure all

gaskets and components are present. Liberty Pumps GR20 Guide

Rail System features a self-aligning mounting bracket. Contact

Liberty Pumps for more information.

If guide rails are not used, complete all pump-mounted plumbing

at this time, being sure all gaskets and components are present.

Pump

Record information from pump nameplate onto the cover of these

instructions. Complete a visual inspection before lowering into

basin.

Place pump in basin being sure the mounting interface (i.e., guide

rail, torque stop) is engaged correctly.

Vent

Vent basin in accordance with applicable plumbing codes.

Operation

Energizing the control panel or breaker for the first time is

potentially dangerous. Licensed electrical personnel should

be present when the panel or breaker is energized for the first

time. If faults caused by damage or poor installation practices

have not been detected, serious damage, injury or death can

result when power is applied.

Starting System

1.

Verify all plumbing components in the basin are installed

correctly and functional. Verify all valves are open and ready

for pump use.

2.

Double check all wire connections. Re-tighten all factory and

field connections.

3.

Ensure pump has no obstructions.

4.

With all electrical and mechanical connections complete and

secure, turn on power to pump and control panel, if

applicable.

5.

Verify operation of the pump, floats, and alarm circuits.

6.

Run several cycles of water through the system to verify

correct control operation for the installation.

Be certain to complete adequate testing, especially on systems

with multiple pumps or custom control configurations.

RISK OF SERIOUS INJURY OR DEATH