6 | EN

Copyright © Liberty Pumps, Inc. 2021 All rights reserved.

5647000M

Wiring Instructions

Always disconnect pump(s) from power source(s) before

handling or making any adjustments to either the pump(s),

the pump system, or the control panel.

All installation and maintenance of pumps, controls,

protection devices, and general wiring shall be done by

qualified personnel.

All electrical and safety practices shall be in accordance with

the National Electrical Code

®

, the Occupational Safety and

Health Administration, or applicable local codes and

ordinances.

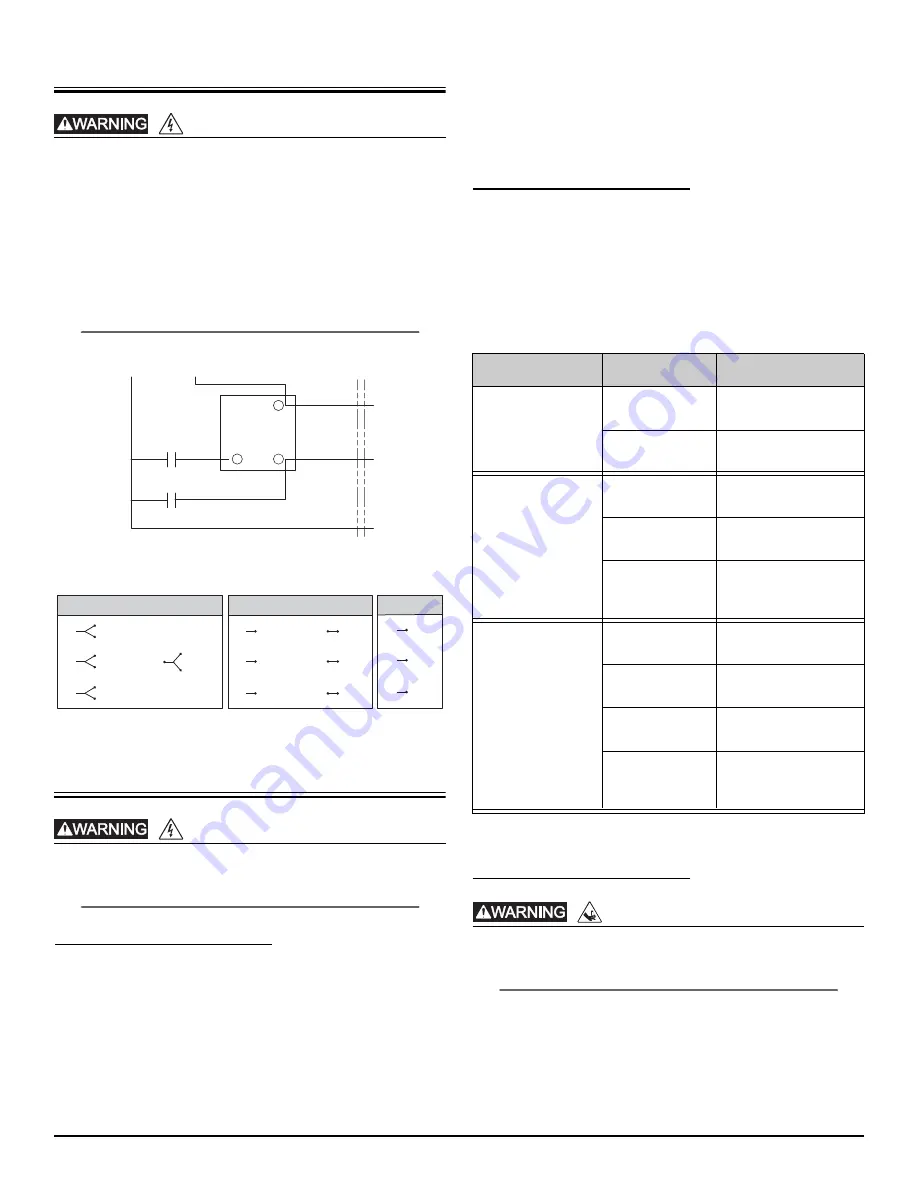

Figure 1. Wiring Diagram 1-Phase, External Capacitor

Figure 2. Wiring Connections 3-Phase

Preparation

Always disconnect pump(s) from power source(s) before

handling or making any adjustments to either the pump(s),

the pump system, or the control panel.

Prepare Basin

The basin required for effluent and sewage applications must be

sealed and vented to meet health and plumbing code

requirements. If replacing a previously installed pump, prepare the

basin by removing the old pump and cleaning any debris from the

basin. Inspect all remaining equipment in the basin including

guide rails, piping, valves, and electrical junction boxes (if present)

and repair or replace as appropriate. Ensure that control hardware

such as floats or pressure transducers are clean, properly adjusted,

and in good working order.

Pump installation should be at a sufficient depth to ensure that all

plumbing is below the frost line. If this is not feasible, remove the

check valve and size the basin and/or adjust pump differential to

accommodate the additional backflow volume. Consult Liberty

Pumps for details on how this should be done.

Pump Control and Alarm Floats

The engineering drawings will generally specify the levels for

Pump ON, Pump OFF, and HIGH LEVEL ALARM. If they are not

specified, the guidelines in Table 2 should be used to determine

float switch locations. The upper water level should be positioned

to minimize pump starts. The HIGH LEVEL ALARM float must be

above the Pump ON float but below any inlets. No float should be

set above the inlet to the basin.

System

Float

Levels

Factory set at float

tether 4”.

Factory set at float

tether 4”.

Level to top of motor

housing.

Minimum 1-1/2’ above

pump OFF level.

Minimum 1’ above

pump ON level and

below inlet pipe.

Level to top of motor

housing.

Minimum 1-1/2’ above

pump OFF level.

Minimum 1’ above

lead pump ON level.

Minimum 1’ above lag

pump ON level and

below inlet pipe.

Cutter and Impeller Free Movement Check

Wear Personal Protective Equipment to protect hands as

cutter blades have extremely sharp edges and present a

serious cutting hazard.

Do not connect any power to pump until this check is complete.

Manually rotate the cutter to check that it spins freely with very

little resistance. The cutter is located on the bottom of the pump.

The cutter can be carefully rotated by hand, or rotated by

inserting a tool into the cutter bolt. If rotating by hand, wear

protective gloves as the cutter and cutter plate have sharp edges.

RISK OF ELECTRIC SHOCK

RISK OF ELECTRIC SHOCK

Black (2)

Red (8)

White (7)

START CAP

RUN CAP

START

RELAY

L1

L2

5

1

2

EXTERNAL CONNECTIONS

L3

L2

L1

black

pink

violet

red

white

blue

brown

orange

yellow

440–480V 3PH

L3

L2

L1

black

pink

violet

575V 3PH

black

pink

violet

red

white

blue

brown

orange

yellow

L3

L2

L1

208V/230V 3PH

Table 2. Float Switch Installation Guidelines

Piggyback Switch

(1-Float System)

OFF

ON

Simplex Pump

Station

(3-Float System)

OFF

ON

HIGH LEVEL

ALARM

Duplex Pump

Station

(4-Float System)

OFF

Lead Pump ON

Lag Pump ON

HIGH LEVEL

ALARM

RISK OF SERIOUS INJURY OR DEATH