22

4. DMD Panel Alignment

Equipment:

-

Pattern Generator

Procedure:

1. Connect power, Video signal into projector.

2. Light on projector

3. Change pattern generator to full white pattern.

4. Watch the image if any pixel lost

5. Change pattern to full black.

6. Watch the image if any pixel lost

7. Change pattern from full black to full white.

8. Watch the image if any pixel can not return

9. Change pattern from full black to full white.

10. Watch the image if any pixel can not return

11. If above 8 step has some pixel lost or can not return, it

s DMD chip has pixel defect

12. Change to the Slid Line pattern

13. Watch the image if any pixel lost

14. If above step has some pixel lost, it

s conductive rubber has defect or assembly

loosed.

5. Optical Engine Assembly Procedure

Note:

Every operator must check the dust/chip on every optical component before assembly.

No

.

Stop

Check

Action

Review

Equipment

Chk Timing Tape of

Color Wheel

Assemble

Color

Wheel

Rotate CW Screw Driver(M3) and Jig

fixture for Color Wheel

Assemble

CW_Sensor

Screw Driver(M2) for

CW/Sensor

Assemble UV-IR on

PLT CW

Direction of

UV-IR

Assemble

PLT CW

Screw Driver(M3)

1 Assy Hsg CW

Tape

CW FPC

and

Sensor FPC

together

Summary of Contents for RD-JT51

Page 13: ...13 2 JT50 52 ...

Page 14: ...14 7 Packaging Description 1 JT51 ...

Page 15: ...15 2 JT50 52 ...

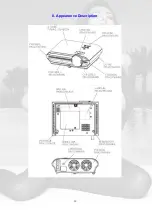

Page 16: ...16 8 Appearance Description ...

Page 53: ...ëí 5 PFC BOARD 6 DC DC BOARD ...

Page 54: ...ëì JT50 52 1 Final Assembly Trouble Shooting Guide ...

Page 55: ...ëë ...

Page 56: ...ëê 2 Engine Assembly Trouble Shooting Guide ...

Page 58: ...ëè 4 Power Supply Trouble Shooting Guide PFC BOARD DX850 DC DC BOARD ...

Page 59: ...5ç 5 DMD Block Trouble Shooting Guide ...

Page 60: ...êð ...

Page 74: ...éì Step 7 Download finished Step 8 Turn off the power switch ...

Page 81: ......