25

INSTALLATION

ENGLISH

5

Attach the two hot leads (black and red) of the

power cord to the outer terminal block

screws.

6

Attach the neutral (white) wire to the center

screw of the terminal block.

7

Attach the power cord ground wire to the

green ground screw.

8

Tighten all screws securely.

9

Reinstall the terminal block access cover.

a

White Wire moved from Ground Screw

b

Hot Leads of Power Cord (Black and Red)

c

Neutral Wire (White)

d

Power Cord Ground Wire

e

Ground Screw

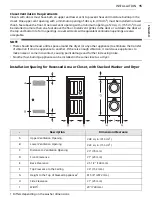

Four-Wire Direct Wire

1

Remove 5 inches (12.7 cm) of the outer

covering from the wire and remove 5 inches

of insulation from the ground wire. Cut off

approximately 1.5 inches (3.8 cm) from the

other three wires and strip 1 inch (2.5 cm)

insulation from each wire. Bend the ends of

the three shorter wires into a hook shape.

a

Ground Wire

2

Remove the terminal block access cover on

the upper back of the appliance.

3

Install UL-listed strain relief into the power

cord through-hole.

4

Thread the 4-wire #10 AWG minimum copper

power cable prepared in step 1 through the

strain relief.

a

Terminal Block

b

UL-Listed Strain Relief

c

UL-Listed 4-Wire Power Cord

5

Transfer the appliance's ground wire from

behind the green ground screw to the center

of the terminal block.

6

Attach the two hot leads (black and red) of the

power cord to the outer terminal block

screws.

7

Attach the neutral (white) wire to the center

screw of the terminal block.

8

Attach the power cord ground wire to the

green ground screw.

9

Tighten all screws securely.

10

Reinstall the terminal block access cover.

• A UL-listed strain relief is

required.

• Use UL-listed 4-wire #10 AWG minimum

copper conductor cable. Allow at least 5 ft. (1.5

m) of wire to allow for removal and

reinstallation of the dryer.

a

b

b

c

d

e

5’’ (12.7 cm)

1’’ (2.5 cm)

a

a

b

c