6. FUNCTIONS

42

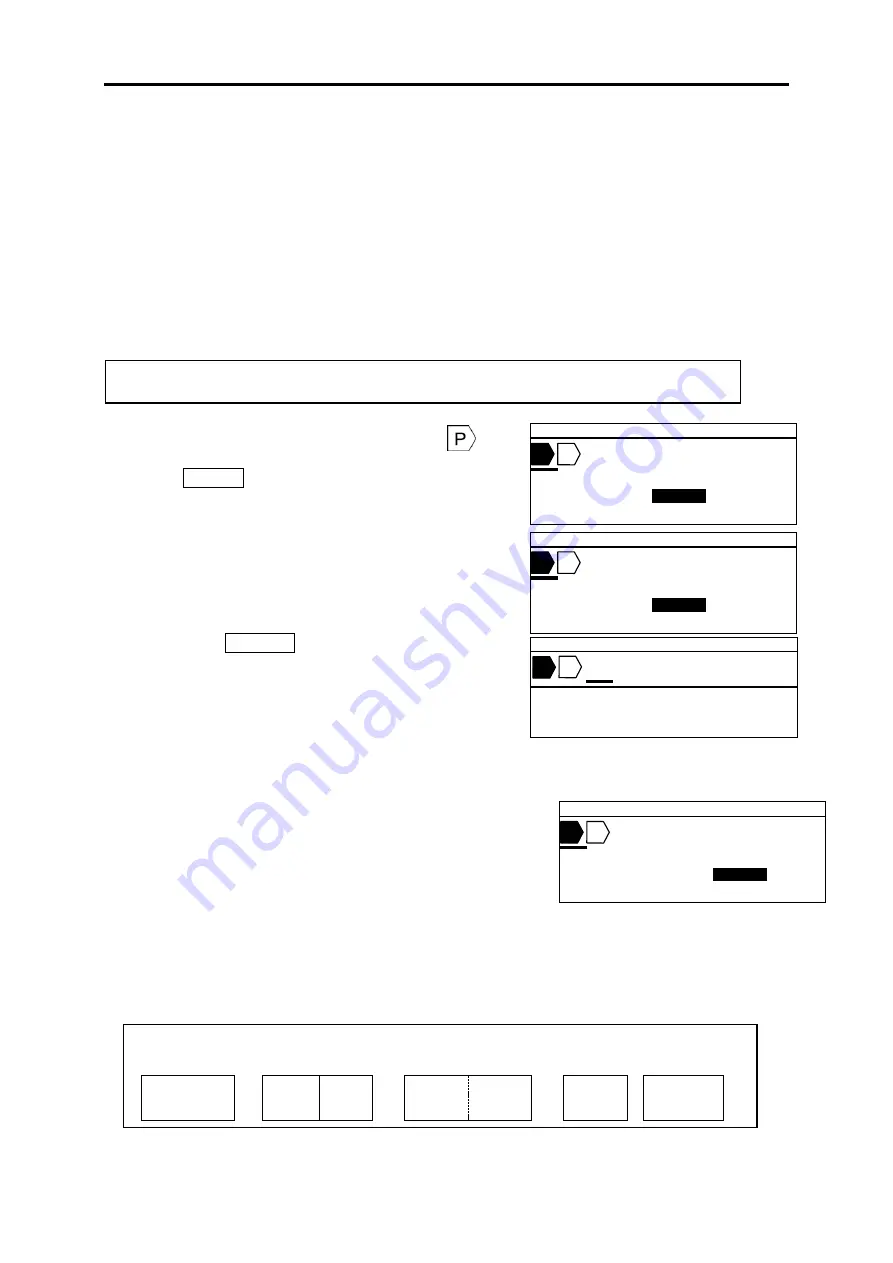

6-4-1 PITCH LENGTH

Setting

the “

PITCH LENGTH

” at the cursor position.

1. Press

◄/► key to move the cursor under

and

press PITCH .

The [

PITCH LENGTH setting screen

] appears.

2. Press

◄/► key or Ten key to input the value of the

“

PITCH LENGTH

.”

3. By pressing ENTER

, the “

PITCH LENGTH

” is set

and the [

INPUT screen

] appears.

Note:

Up to

5

different “

PITCH LENGTH

” can be set in one document..

● The default value of “

PITCH LENGTH

” can be changed in the “OPTION” setting.

(

“

AUTO

”

pitch function

)

By pressing

▲/▼, “

AUTO

” is selectable as “

PITCH LENGTH

”

for TUBE only.

Note:

When

“AUTO” is selected, pitch length is automatically

adjusted according to the number of characters,

character size, character width, etc.

6-4-2 PITCH CUT

Setting how to divide each block.

Selectable items:

No

LINE

DOTS

HALF-CUTTING

ABC 123

ABC

123

ABC

123

ABC

123

Setti

ng range: “Tube” = AUTO or 10.0

~

60.0mm, “Tape” = AUTO or 4.0

~

60.0mm

▲

2 0 . 0 C U T 0 0 1

A B C

P I T C H L E N G T H

=

2 0 . 0

m m

B

P

▲

2 0 . 0 C U T 0 0 1

A B C

P I T C H L E N G T H

=

3 0 . 0

m m

B

P

▲

3 0 . 0 C U T 0 0 1

A B C

T U B E 3 .2 m m

AUTO STD STD 002

B

P

▲

2 0 . 0 C U T 0 0 1

A B C

P I T C H L E N G T H

=

A U T O

B

P

Summary of Contents for MAX LM-550A/PC A11

Page 1: ......