Page 24 - IOM / ROOF-TOP FLEXY™ Series

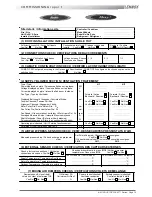

AIRFLOW BALANCING

2nd method when adjusting the pulley :

- Close the pulley fully and count the number of turns

from fully closed position. Using table 1 determine the

motor pulley actual diameter.

- Record the fix fan pulley diameter.(DF)

- Determine the fan speed using the following formula:

rpm FAN = rpm MOTOR x DM / DF

Where :

rpm MOTOR : ....... from the motor plate or table 2

DM : ...................... from table 1

DF: ........................ from machine

Once the pulleys are adjusted and the belt checked and

tensioned, start the fan motor and record the Amps and

Voltage between the phases :

Using the measured data and table 2

- Theoretical mechanical power at the fan shaft :

P

meca fan

= P

meca Motor

x

η

Transmission

P

meca fan

= P

elec

x

η

meca motor

x

η

Transmission

P

meca fan

= V x I x

√

3 x cos

ϕ

x

η

meca motor

x

η

Transmission

This formula can be approximated in this way

P

meca fan

= V x I x 1.73 x 0.85 x 0.76 x 0.9

With the fan "rpm" and the mechanical power at the fan shaft

an operating point and the supplied airflow can be estimated

using the fan curves.

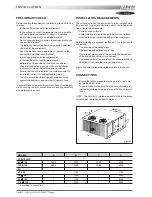

CHECKING AIRFLOW AND ESP

Using the fan curves on page 25, 26, 27, the airflow, the total

pressure available (P

TOT

) and the corresponding dynamic

pressure (Pd) can now be estimated, for a specific operating

point;

The next step consist in estimating the pressure losses across

the unit.

This can be achieved using the "dirty filter pressure sensor"

and the accessories pressure drop table:

Also the pressure drop due to the duct inlet into the roof-top

unit can be taken as 20 to 30 Pa.

∆

P

INT

=

∆

P

filter

+ coil + P

Inlet

+

∆

P

Options

using the results from above, the external static pressure (ESP)

can then be estimated:

ESP = P

TOT

- Pd -

∆

P

INT

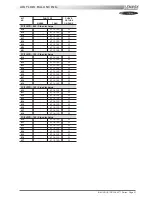

Table 2

Motor Size

Nom, Speed

Cos

meca motor

0,75 kW

1400 rpm

0,77

0,70

1,1 kW

1425 rpm

0,82

0,77

1,5 kW

1430 rpm

0,81

0,75

2,2 kW

1430 rpm

0,81

0,76

3,0 kW

1425 rpm

0,78

0,77

4 kW

1425 rpm

0,79

0,80

5,5 kW

1430 rpm

0,82

0,82

Economiser

EU7

Hot water coil

Electric heater

Roofcurb

Horizontal

Gaz

100% open

Filter

S

H

S

H

Base frame

Roofcurb

H

SIZE

Air flow (m

3

/h)

(Pa)

(Pa)

(Pa)

(Pa)

(Pa)

(Pa)

(Pa)

(Pa)

(Pa)

Min.

10 000

4

67

12

14

5

8

10

41

22

60

Nom.

12 000

6

93

16

19

8

8

11

59

26

Max.

15 000

9

135

24

28

8

10

13

92

31

Min.

12 000

6

56

6

12

5

5

13

59

29

70

Nom.

14 000

8

73

8

16

5

5

16

80

34

Max.

18 000

12

113

13

25

8

8

22

132

47

Min.

14 000

8

73

8

16

5

8

18

44

7

85

Nom.

16 000

10

113

13

25

8

8

26

57

10

Max.

22 000

16

159

18

36

8

10

32

109

12

Min.

16 000

10

93

10

20

8

10

26

57

10

100

Nom.

20 000

14

135

15

30

10

13

32

90

12

Max.

22 000

16

159

18

36

13

15

38

109

15

Min.

18 000

12

113

13

25

10

13

32

33

29

120

Nom.

22 000

16

159

18

36

13

15

38

49

35

Max.

24 000

18

184

21

41

15

18

44

58

40

Min.

20 000

14

135

15

30

10

15

35

40

31

140

Nom.

24 000

18

184

21

41

15

18

46

58

40

Max.

25 000

19

197

22

44

15

20

50

63

43

Min.

22 000

16

87

9

18

8

8

24

49

45

160

Nom.

28 000

22

132

13

27

8

10

30

79

56

Max.

32 000

26

165

17

34

13

13

34

103

64

Min.

24 000

18

101

10

20

10

10

34

58

64

190

Nom.

33 000

27

174

18

36

13

13

41

109

77

Max.

36 000

30

201

21

41

13

15

48

130

89

Table 5.52

Summary of Contents for ROOFTOP FLEXY FCA 100

Page 1: ...INSTALLATION OPERATING MAINTENANCE MANUAL ROOFTOP FLEXY English August 2003 ...

Page 2: ......

Page 33: ...IOM ROOF TOP FLEXY Series Page 31 AIR FLOW BALANCING AT 12 12 FAN ...

Page 34: ...Page 32 IOM ROOF TOP FLEXY Series AIR FLOW BALANCING AT 15 15 FAN ...

Page 35: ...IOM ROOF TOP FLEXY Series Page 33 AIR FLOW BALANCING AT 18 13 ...

Page 36: ...Page 34 IOM ROOF TOP FLEXY Series AIR FLOW BALANCING AT 18 18 FAN ...

Page 37: ...IOM ROOF TOP FLEXY Series Page 35 AIR FLOW BALANCING RDN 450 FAN ...

Page 38: ...Page 36 IOM ROOF TOP FLEXY Series AIR FLOW BALANCING ADN 355 FAN ...

Page 39: ...IOM ROOF TOP FLEXY Series Page 37 AIR FLOW BALANCING ADN 400 FAN ...

Page 40: ...Page 38 IOM ROOF TOP FLEXY Series AIR FLOW BALANCING ADN 450 FAN ...

Page 104: ...Page 102 IOM ROOF TOP FLEXY Series ELECTRICAL WIRING DIAGRAMS MAIN CURRENT DIAGRAM ...

Page 106: ...Page 104 IOM ROOF TOP FLEXY Series ELECTRICAL WIRING DIAGRAMS CLIMATIC CONTROLLER ...

Page 108: ...Page 106 IOM ROOF TOP FLEXY Series ELECTRICAL WIRING DIAGRAMS CLIMATIC INPUT FG FD ...

Page 112: ...Page 110 IOM ROOF TOP FLEXY Series ELECTRICAL WIRING DIAGRAMS GAS BURNER 180 Kw ...

Page 132: ...Page 130 IOM ROOF TOP FLEXY Series ISO 9001 CERTIFICATION ...

Page 133: ...IOM ROOF TOP FLEXY Series Page 131 PED CERTIFICATION OF CONFORMITY ...

Page 134: ...Page 132 IOM ROOF TOP FLEXY Series GLASS WOOL FIRE CLASS ...

Page 135: ...IOM ROOF TOP FLEXY Series Page 133 33 kW GAS BURNER CE CERTIFICATION OF CONFORMITY ...

Page 136: ...Page 134 IOM ROOF TOP FLEXY Series 60 kW GAS BURNER CE CERTIFICATION OF CONFORMITY ...

Page 137: ...IOM ROOF TOP FLEXY Series Page 135 120 kW GAS BURNER CE CERTIFICATION OF CONFORMITY ...

Page 138: ...Page 136 IOM ROOF TOP FLEXY Series 180 kW GAS BURNER CE CERTIFICATION OF CONFORMITY ...

Page 139: ...IOM ROOF TOP FLEXY Series Page 137 INSULATION FIRE CLASS ...

Page 140: ...Page 138 IOM ROOF TOP FLEXY Series INSULATION FIRE CLASS ...

Page 141: ......