Page 4

Requirements

CAUTION

When venting this appliance, keep vent terminal

free of snow, ice and debris.

CAUTION

Physical contact with metal edges and corners

while applying excessive force or rapid motion can

result in personal injury. Be aware of, and use

caution when working near these areas during

installation or while servicing this equipment.

S

Installation of Lennox oil−fired furnaces must conform

with the National Fire Protection Association Standard

for the Installation of Oil Burning Equipment, NFPA

No. 31, the National Electrical Code, ANSI/NFPA

No.70 (in the U.S.A.), CSA Standard CAN/CSA−B139

(in Canada), Installation Code for Oil Burning Equip-

ment, the Canadian Electrical Code Part1, CSA 22.1

(Canada), the recommendations of the National Envi-

ronmental Systems Contractors Association and any

state or provincial laws or local ordinances. Authorities

having jurisdiction should be consulted before installa-

tion. Such applicable regulations or requirements take

precedence over general instructions in this manual.

S

Chimneys and chimney connectors must be of the

type and construction outlined in section 160 of NFPA

No. 31.

S

Air for combustion and ventilation must conform to

standards outlined in section 140 of NFPA No. 31 or,

in Canada, CSA Standard B139. When installing

O23V units in confined spaces such as utility rooms,

two combustion air openings are required. Dimen-

sions of combustion air openings are shown in table 1.

One opening shall be below burner level and the other

opening shall be no more than 6"(152 mm) from the

room’s ceiling.

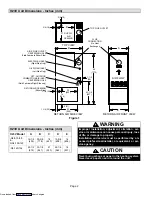

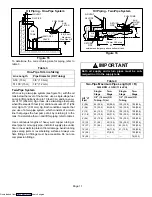

Table 1

Combustion Air Opening Dimensions

Model No.

(2 openings required)

O23V−70/90/105/120 10" X 20" (254 mm X 508 mm)

O23V−140/154

11" X 22" (279 mm X 559 mm)

S

This unit is approved for use on combustible flooring

and for clearances to combustible material as listed on

unit rating plate and in table 2. Unit service and acces-

sibility clearances take precedence over fire protec-

tion clearances.

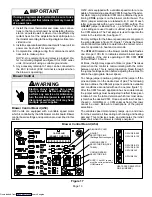

IMPORTANT

An opening to the outside for combustion air is

strongly recommended, especially in new homes.

Refer to table 1 or the unit rating plate for specific

combustion air opening dimensions.

S

The combustion air opening should provide a mini-

mum free area one-half square inch per 1,000 Btu per

hour input. This combustion air should be brought into

the area containing the furnace below the level of the

furnace burner.

Table 2

O23V Installation Clearances

Clearances

inches (mm)

top of plenum & duct

2 (51)

plenum sides

3 (76)

sides

0 (0)

rear

0 (0)

front

4 (120)

flue pipe

6 (152)

S

With the HEAT selector pin in the position shown in the

wiring diagram (on page 16), the unit must operate at

a temperature rise in the range listed in table 7 (on

page 17).

S

When installed, furnace must be electrically grounded

in accordance with local codes or, in the absence of lo-

cal codes, with the current National Electric Code,

ANSI/NFPA No. 70, or Canadian Electric Code (CEC)

if an external electrical source is utilized.

S

Field wiring connections with the unit must meet or ex-

ceed specifications of type T wire and must withstand

a 63

_

F (17

_

C) temperature rise.

S

If installing a programmable thermostat, use a type

which retains its memory in event of a power loss.

S

When the furnace is used in conjunction with cooling

units, it shall be installed in parallel with, or on the up-

stream side of, cooling units to avoid condensation in

the heating element. With a parallel flow arrangement,

a damper (or other means to control the flow of air)

shall be adequate to prevent chilled air from entering

the furnace and, if manually operated, must be

equipped with means to prevent operation of either

unit, unless damper is in the full heat" or cool" posi-

tion.

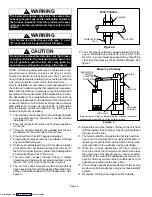

WARNING

When an air conditioning unit is used in conjunc-

tion with the furnace, the evaporator coil must be

installed in the discharge (supply) air. Do not install

an evaporator coil in the return air; excessive con-

densation will occur within the furnace.

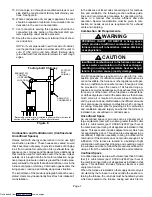

Locate & Level the Unit

Set the unit in desired location keeping in mind the clear-

ances listed in table 2. Also keep in mind oil supply connec-

tions, electrical supply, flue connections and sufficient

clearance for installing and servicing unit.

Level the unit from side to side and from front to rear. If the

furnace is not level, place fireproof wedges or shims be-

tween the low side of the furnace and the floor. Make sure

the weight of the furnace is distributed evenly on all four

corners. Strain on sides of cabinet causing cracking and

popping noises may occur if weight of furnace is not evenly

distributed.

Downloaded from