Page 15

Continuous Fan

When the thermostat is set for Continuous Fan" operation

and there is no demand for heating or cooling, the blower

control will provide 50% of the

COOL

CFM selected.

OFF

CALL

50%

G

g

G − Fan switch ON

g − Fan switch OFF

NOTE − With the proper thermostat and subbase, continu-

ous blower operation is possible by closing the R to G cir-

cuit.

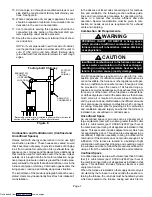

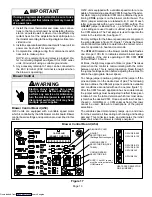

Dehumidification

The A54 blower control board (see figure 17) includes a

HUM terminal which provides for connection of a humidis-

tat. The JW1 jumper on the blower control board must be

cut to activate the HUM terminal. The humidistat must be

wired to open on humidity rise. When the dehumidification

circuit is used, the variable speed motor will reduce the se-

lected air flow rate by 18% when humidity levels are high.

An LED (D1) lights when the blower is operating in the de-

humidification mode.

Humidification

Terminals are provided on the A15 control board for 120

volt output to operate a humidifier. The HUM" terminal is

energized when there is a call for heat. See figure 18.

Electronic Air Cleaner

Terminals are provided on A15 control board for 120 volt

output to an electronic air cleaner. The EAC" terminal is

energized when there is a call for heat, cool, or continuous

blower. See figure 18.

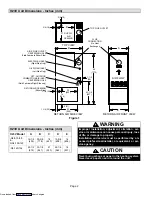

Table 6

Blower Performance

{0 through 0.80 in. w.g. (0 through 200 Pa) External Static Pressure Range}

ADJUST"

Jumper

Setting

HEAT" Jumper Speed Position [kBtuh heat input]

COOL" Jumper Speed Position

A

B

C

D

A

B

C

D

cfm

L/s

cfm

L/s

cfm

L/s

cfm

L/s

cfm

L/s

cfm

L/s

cfm

L/s

cfm

L/s

Model O23V2/3−70/90 Units

Do not use

Do not use

[−90]

[−70]

(+)

N/A

N/A

N/A

N/A

Same as NORM

1380

650

1150

545

920

435

690

325

NORM

N/A

N/A

N/A

N/A

1000

470

750

355

1200

565

1000

470

800

380

600

285

(–)

N/A

N/A

N/A

N/A

Same as NORM

1020

480

850

400

680

320

510

240

Model O23V3/4−105/120 Units

Do not use

Do not use

[−120]

[−105]

(+)

N/A

N/A

N/A

N/A

Same as NORM

1610

760

1380

650

1150

540

920

435

NORM

N/A

N/A

N/A

N/A

1300

615

1200

565

1400

660

1200

565

1000

470

800

380

(–)

N/A

N/A

N/A

N/A

Same as NORM

1190

560

1020

480

850

400

680

320

Model O23V5−140/154 Units

Do not use

[−154]

Do not use

[−140]

(+)

N/A

N/A

Same as

NORM

N/A

N/A

Same as

NORM

2300

1085

2070

975

1840

870

1380

650

NORM

N/A

N/A

1730

816

N/A

N/A

1400

660

2000

945

1800

850

1600

755

1200

565

(–)

N/A

N/A

Same as

NORM

N/A

N/A

Same as

NORM

1700

800

1530

720

1360

640

1020

480

NOTE − Continuous Fan air volume is 50% of COOL speed.

Downloaded from