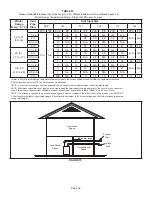

Page 38

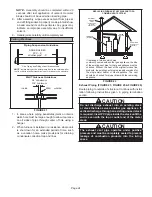

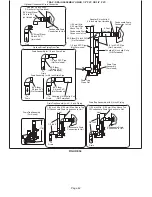

Details of Exhaust Piping Terminations for Non-Direct

Vent Applications

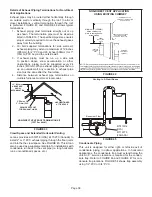

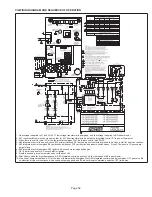

Exhaust pipes may be routed either horizontally through

an outside wall or vertically through the roof. In attic or

closet installations, vertical termination through the roof

is preferred. FIGURE 43 and FIGURE 44 shows typical

terminations.

1 -

Exhaust piping must terminate straight out or up

as shown. The termination pipe must be sized as

listed in TABLE 16. The specified pipe size ensures

proper velocity required to move the exhaust gases

away from the building.

2 - On field supplied terminations for side wall exit,

exhaust piping may extend a maximum of 12 inches

(305mm) for 2” PVC and 20 inches (508mm) for 3”

(76mm) PVC beyond the outside wall.

3 - If exhaust piping must be run up a side wall

to position above snow accumulation or other

obstructions, piping must be supported every 24

inches (610mm). When exhaust piping must be run

up an outside wall, any reduction in exhaust pipe

size must be done after the final elbow.

4 - Distance between exhaust pipe terminations on

multiple furnaces must meet local codes

NON-DIRECT VENT ROOF TERMINATION KIT

(15F75 or 44J41)

UNCONDITIONED

ATTIC SPACE

3” (76mm) OR

2” (51mm) PVC

PROVIDE SUPPORT

FOR EXHAUST LINES

12” (305mm)

ABOVE AVE.

SNOW

ACCUMULATION

FIGURE 43

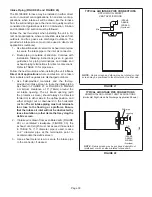

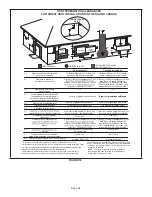

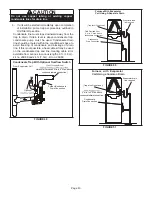

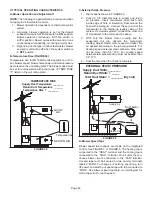

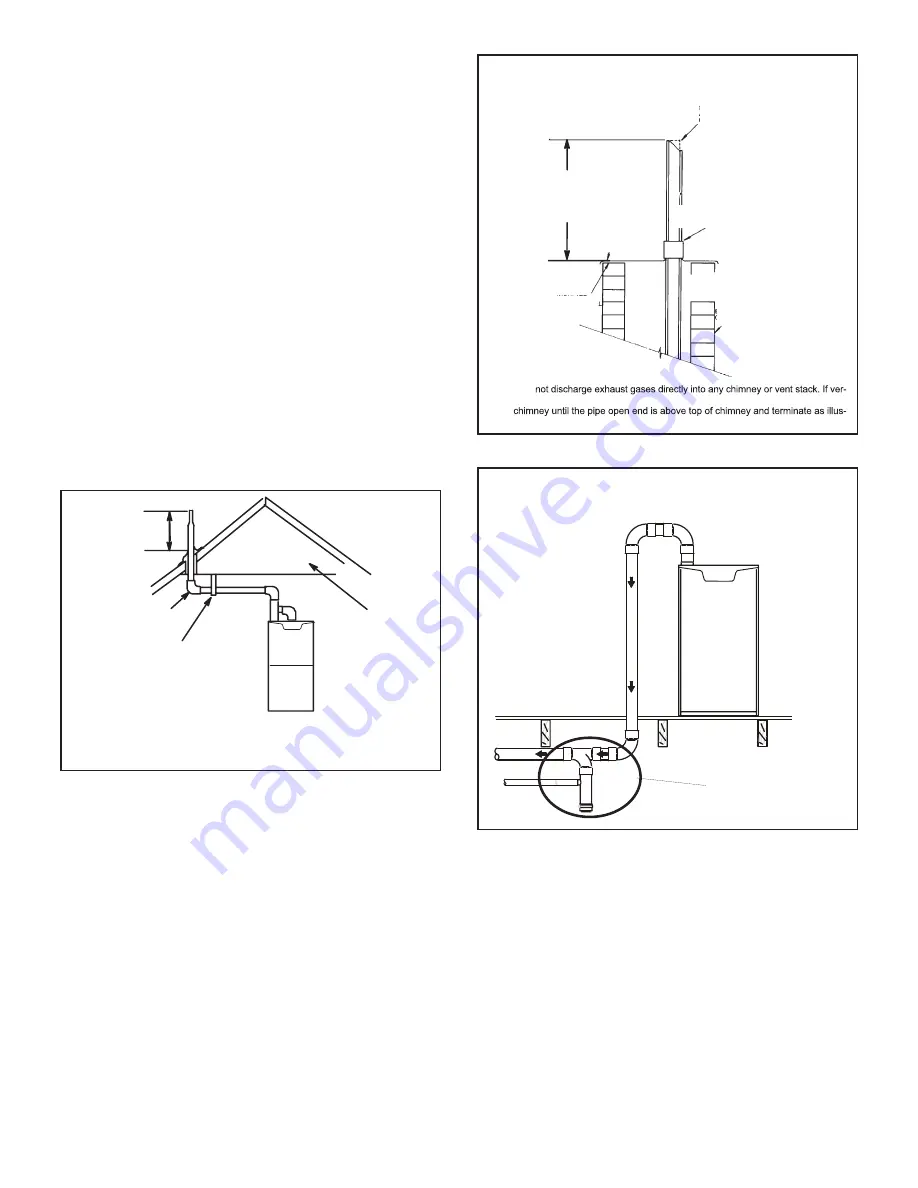

Crawl Space and Extended Horizontal Venting

Lennox provides kit 51W18 (USA) kit 15Z70 (Canada) to

install 2” or 3” PVC exhaust piping through the floor joists

and into the the crawl space. See FIGURE 45. This kit can

also be used as a supplemental drain for installations with

condensate run back in the vent pipe (ie. long horizontal

runs, unconditioned spaces, etc.).

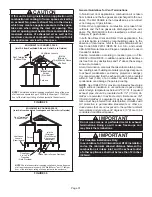

NOTE - Do

tical discharge through an existing unused chimney or stack is required, insert piping

inside

trated. In any exterior portion of chimney, the exhaust vent must be insulated.

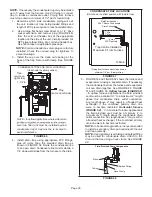

STRAIGHT-CUT OR

ANGLE-CUT IN DIRECTION

OF ROOF SLOPE

SHOULDER OF FITTINGS

PROVIDE SUPPORT

OF PIPE ON TOP PLATE

EXTERIOR

PORTION OF

CHIMNEY

INSULATE

TO FORM

SEAL

SHEET

METAL TOP

PLATE

NON-DIRECT VENT APPLICATION

USING EXISTING CHIMNEY

Minimum 12” (305MM)

above chimney top

plate or average snow

accumulation

FIGURE 44

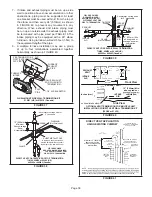

Venting In A Crawl Space

Basement Floor

KIT 51W18

(USA)

KIT 15Z70

(CANADA)

FIGURE 45

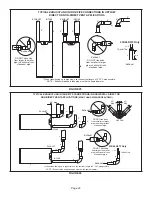

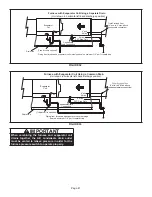

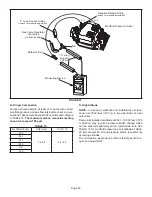

Condensate Piping

This unit is designed for either right- or left-side exit of

condensate piping in upflow applications. In horizontal

applications, the condensate trap must extend below the

unit. An 8” service clearance is required for the conden

-

sate trap. Refer to FIGURE 46 and FIGURE 47 for con

-

densate trap locations. FIGURE 54 shows trap assembly

using 1/2” PVC or 3/4” PVC.

Summary of Contents for ML196UH030XE36B

Page 57: ...Page 57...