Page 13

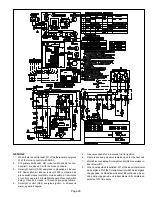

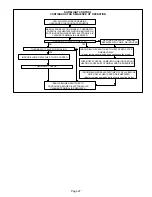

Blower Control Module (Figure 10)

G50UHi units are equipped with a blower control module

which offers a variety of indoor blower speeds for selection.

The module is wired between the SureLight ignition control

board and the indoor blower motor. The module alters the

frequency and voltage of the power supply to the blower to

control blower speed. The module provides consistent

CFM over a wider range of operating static pressures.

The module also features a dehumidification option. This

option requires the use of a thermostat which includes a hu-

midity sensor, as well as a relay, which must both be or-

dered separately. When this optional feature is used, the

blower control module shifts the indoor blower motor to a

lower speed (determined by the selector jumper) when the

indoor thermostat indicates a dehumidification require-

ment.

The module includes a ramping profile selector, which of-

fers passive humidity control during cooling operation. This

feature does not require the use of a specific thermostat or

an additional relay. There are three available ramping pro-

files. When one of the ramping profiles is used, the indoor

blower is initially engaged at a lower speed to provide addi-

tional humidity control. After the selected time period

(7−1/2, 10, or 15 minutes), the blower motor shifts to the

regularly selected cooling speed.

The module/bracket assembly is located on the blower

scroll just below the SureLight control board. Blower

speeds are adjusted by altering the position of blower

speed selector jumpers.

Blower Control Module Settings

DANGER

Disconnect power from unit and

wait at least 30 seconds to allow

capacitors to discharge before re-

moving blower control module

cover. Failure to wait may cause

personal injury or death.

Remove the cover panel from the module to access the se-

lector jumpers. There are five selector pins in each column.

These pins, when jumpered, correspond with four selec-

tion options for each function. The speed (or ramp) selec-

tion is listed in the space between the two pins. There are

eight blower speeds and four ramping options available for

selection on the control module. Refer to table 9 and figure

10. The blower speed settings and the corresponding

CFMs are given in the BLOWER DATA section.

The ramping options provide a means of controlling humid-

ity during cooling operation without the use of a humidity

sensor or additional relay.

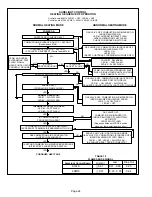

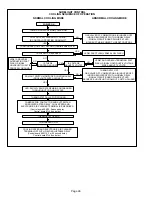

Ramping Option A (Factory Selection)

D

Motor runs at 82% for approximately 7−1/2 minutes.

D

If demand has not been satisfied after 7−1/2 minutes,

motor runs at 100% until demand is satisfied.

D

Once demand is met, motor ramps down to off.

OFF

OFF

82%CFM

100% CFM

COOLING DEMAND

7−1/2 MIN

Ramping Option B

D

Motor runs at 75% for approximately 10 minutes.

D

If demand has not been satisfied after 10 minutes, mo-

tor runs at 100% until demand is satisfied.

D

Once demand is met, motor ramps down to off.

OFF

OFF

75%CFM

100% CFM

COOLING DEMAND

10 MIN

Ramping Option C

D

Motor runs at 75% for approximately 15 minutes.

D

If demand has not been satisfied after 15 minutes, the

motor runs at 100% until demand is satisfied.

D

Once demand is met, motor ramps down to off.

OFF

OFF

75%CFM

100% CFM

COOLING DEMAND

15 MIN

G50UHi BLOWER CONTROL MODULE

6−PIN CONNECTOR

TO SURELIGHT

CONTROL

SELECTOR PINS

WITH JUMPERS

(Options detailed at right)

3−PIN MOTOR

CONNECTOR

FIGURE

COOL

HEAT

FAN

DEHUM.

RAMP

1

1

3

4

2

3

4

5

2

5

6

7

3

4

5

6

OFF

A

B

C

4−Ton and 5−Ton Blowers

COOL

HEAT

FAN DEHUM.

RAMP

1

2

3

4

3−Ton Blower

1

1

3

4

2

5

6

7

3

4

5

6

OFF

A

B

C

Summary of Contents for G50UHi Series

Page 6: ...Page 6 FIGURE 1...