STATIC PRESSURE TEST

FIGURE 22

Page 20

V−TYPICAL OPERATING CHARACTERISTICS

A−Blower Operation and Adjustment

1 − Blower operation is dependent on thermostat control

system.

2 − Generally, blower operation is set at thermostat sub-

base fan switch. With fan switch in ON position, blower

operates continuously. With fan switch in AUTO position,

blower cycles with demand or runs continuously while

heating or cooling circuit cycles.

3 − Depending on the type of indoor thermostat, blower

and entire unit will be off when the system switch is in

OFF position.

B−Temperature Rise

Temperature rise for G50UHi units depends on unit input,

blower speed, blower horsepower and static pressure as

marked on the unit rating plate. The blower speed must be

set for unit operation within the range of TEMP. RISE

°

F"

listed on the unit rating plate.

To Measure Temperature Rise:

1 − Place plenum thermometers in the supply and return air

plenums. Locate supply air thermometer in the first hori-

zontal run of the plenum where it will not pick up radiant

heat from the heat exchanger.

2 − Set thermostat to highest setting.

3 − After plenum thermometers have reached their high-

est and steadiest readings, subtract the two readings.

The difference should be in the range listed on the unit

rating plate. If the temperature is too low, decrease

blower speed. If temperature is too high, first check the

firing rate. Provided the firing rate is acceptable, in-

crease blower speed to reduce temperature.

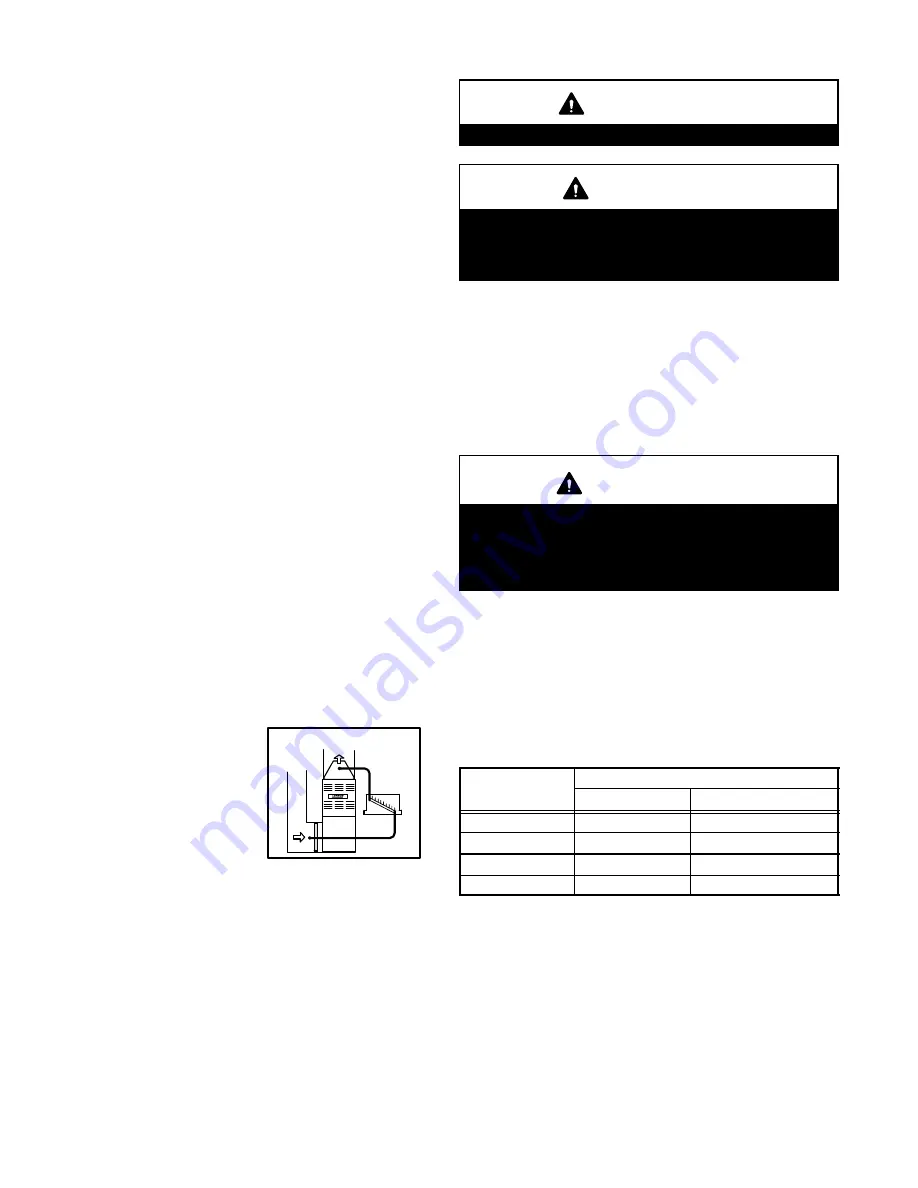

C−External Static Pressure

1 − Tap locations shown in figure 22 .

2 − Punch a 1/4" diameter hole

in supply and return air ple-

nums. Insert manometer

hose flush with inside edge

of hole or insulation. Seal

around the hose with perma-

gum. Connect the zero end

of the manometer to the dis-

charge (supply) side of the system. On ducted sys-

tems, connect the other end of manometer to the return

duct as above. For systems with non−ducted returns,

leave the other end of the manometer open to the at-

mosphere.

3 − With only the blower motor running and the evaporator

coil dry, observe the manometer reading. Adjust blow-

er motor speed to deliver the air desired according to

the job requirements.

4 − External static pressure drop must not be more than

0.5" W.C.

5 − Seal around the hole when the check is complete.

VI−MAINTENANCE

WARNING

Disconnect power before servicing unit.

CAUTION

Label all wires prior to disconnection when servicing

controls. Wiring errors can cause improper and dan-

gerous operation. Verify proper operation after ser-

vicing.

At the beginning of each heating season, a qualified techni-

cian should check the system as follows:

Blower

Check the blower wheel for debris and clean if necessary.

The blower motors are prelubricated for extended bearing

life. No further lubrication is needed.

WARNING

The blower access panel must be securely in place

when the blower and burners are operating. Gas

fumes, which could contain carbon monoxide, can

be drawn into living space resulting in personal inju-

ry or death.

Filters

All G50UHi filters are installed external to the unit. Filters

should be inspected monthly. Clean or replace the filters

when necessary to ensure that the furnace operates prop-

erly. Replacement filters must be rated for high velocity air-

flow. Table 18 lists recommended filter sizes.

TABLE 18

Furnace

Filter Size

Furnace

Cabinet Size

Side Return

Bottom Return

14−1/2"

16 X 25 X 1 (1)

14 X 25 X 1 (1)

17−1/2"

16 X 25 X 1 (1)

16 X 25 X 1 (1)

21"

16 X 25 X 1 (1)

20 X 25 X 1 (1)

24−1/2"

16 X 25 X 1 (2)

24 X 25 X 1 (1)

Flue And Chimney

Check the flue pipe, chimney and all connections for tight-

ness and to make sure there is no blockage.

Electrical

1 − Check all wiring for loose connections.

2 − Check for the correct voltage at the furnace (furnace

operating).

3 − Check amp−draw on the blower motor.

Motor Nameplate__________Actual__________

Summary of Contents for G50UHi Series

Page 6: ...Page 6 FIGURE 1...