Page 17

Set points vary depending on unit size. See table 13. The

pressure sensed by the switch is negative relative to atmo-

spheric pressure. If the flue becomes obstructed during op-

eration, the switch senses a loss of negative pressure

(pressure becomes more equal with atmospheric pres-

sure) and opens the circuit to the furnace control and gas

valve. A bleed port on the switch allows relatively dry air in

the vestibule to purge switch tubing, to prevent condensate

build up.

The switch is factory set and is not field adjustable. It is a

safety shut-down control in the furnace and must not be by−

passed for any reason. If switch is closed or by−passed, the

control will not initiate ignition at start up.

TABLE 13

G50UHi Unit

Set

Point

High Altitude

Set Point

4501’ − 7500’

High Altitude

Set Point

7500’ − 10,000’

−070

0.47"

0.36"

0.36"

−090

0.51"

0.47"

0.43"

−110

0.58"

0.47"

0.43"

−135

0.51"

0.47"

0.43"

II−PLACEMENT AND INSTALLATION

Make sure unit is installed in accordance with installation

instructions and applicable codes.

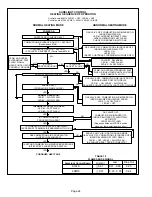

III−START-UP

A−Preliminary and Seasonal Checks

1 − Inspect electrical wiring, both field and factory installed

for loose connections. Tighten as required.

2 − Check voltage at disconnect switch. Voltage must be

within range listed on the nameplate. If not, consult the

power company and have voltage condition corrected

before starting unit.

B−Heating Start-Up

WARNING

Shock and burn hazard. G50UHi units are equipped

with a hot surface ignition system. Do not attempt to

light manually.

1 −

STOP

! Read the safety information at the beginning of

this section.

2 − Set thermostat to lowest setting.

3 − Turn off all electrical power to appliance.

4 − This appliance is equipped with an ignition device

which automatically lights the burners. Do

not

try to

light the burners by hand.

5 − Remove top access panel.

6 −

White Rodgers Gas Valve −−

Switch lever to

OFF

.

See figure 16.

Honeywell Gas Valve −−

Turn knob on

gas valve clockwise

to

OFF

. Do not force. See

figure 18.

7 − Wait five (5) minutes to clear out any gas. If you then

smell gas,

STOP

! Immediately call your gas supplier from

a neighbor’s phone. Follow the gas supplier’s instruc-

tions. If you do not smell gas go to next step.

8 −

White Rodgers Gas Valve −−

Switch gas valve lever to

ON

.

Honeywell Gas Valve −−

Turn knob on gas valve coun-

terclockwise

to

ON

. Do not force.

9 − Replace access panel.

10− Turn on all electrical power to unit.

11− Set thermostat to desired setting.

12− If the appliance will not operate, follow the instructions

To Turn Off Gas To Unit" and call your service techni-

cian or gas supplier.

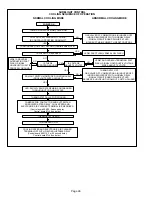

Turning Off Gas To Unit

1 − Set thermostat to lowest setting.

2 − Turn off all electrical power to unit if service is to be per-

formed.

3 − Remove access panel.

4 − Switch lever on White Rodgers gas valve to

OFF

; turn

knob on Honeywell valve clockwise

to

OFF

. Do not

force.

5 − Replace access panel.

C−Safety or Emergency Shutdown

Turn off unit power. Close manual and main gas valves.

D−Extended Period Shutdown

Turn off thermostat or set to UNOCCUPIED" mode. Close

all gas valves (both internal and external to unit) to guaran-

tee no gas leak into combustion chamber. Turn off power to

unit. All access panels and covers must be in place and se-

cured.

IV−HEATING SYSTEM SERVICE CHECKS

A−C.S.A. Certification

All units are C.S.A. (formally A.G.A. and C.G.A. combined)

design certified without modifications. Refer to the G50UHi

Installation Instruction.

B−Gas Piping

CAUTION

If a flexible gas connector is required or allowed by

the authority that has jurisdiction, black iron pipe

shall be installed at the gas valve and extend outside

the furnace cabinet.

WARNING

Do not exceed 600 in−lbs (50 ft−lbs) torque when

attaching the gas piping to the gas valve.

Gas supply piping should not allow more than 0.5"W.C. drop

in pressure between gas meter and unit. Supply gas pipe

must not be smaller than unit gas connection

Compounds used on gas piping threaded joints should be

resistant to action of liquefied petroleum gases.

Summary of Contents for G50UHi Series

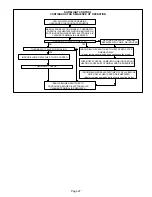

Page 6: ...Page 6 FIGURE 1...