Page 4

Requirements

All G23(X) units are Canadian Standards Association

(CSA) certified.

In the USA, installation of Lennox gas central furnaces

must conform with local building codes. In the absence of

local codes, units must be installed according to the cur

rent National Fuel Gas Code (ANSIZ223.1) in the United

States. The National Fuel Gas Code is available from the

following address:

American National Standards Institute, Inc.

11 West 42nd Street

New York, NY 10036

Air supply for combustion and ventilation must conform to

the methods outlined in the current National Fuel Gas Code.

WARNING

Product contains fiberglass wool.

Disturbing the insulation in this product during

installation, maintenance, or repair will expose you

to fiberglass wool dust. Breathing this may cause

lung cancer. (Fiberglass wool is known to the State

of California to cause cancer.)

Fiberglass wool may also cause respiratory, skin,

and eye irritation.

To reduce exposure to this substance or for further

information, consult material safety data sheets

available from address shown below, or contact

your supervisor.

Lennox Industries Inc.

P.O. Box 799900

Dallas, TX 75379-9900

This furnace is CSA certified for installation clearances to

combustible material as listed on the unit rating plate and

in table 1. Accessibility and service clearances must take

precedence over fire protection clearances.

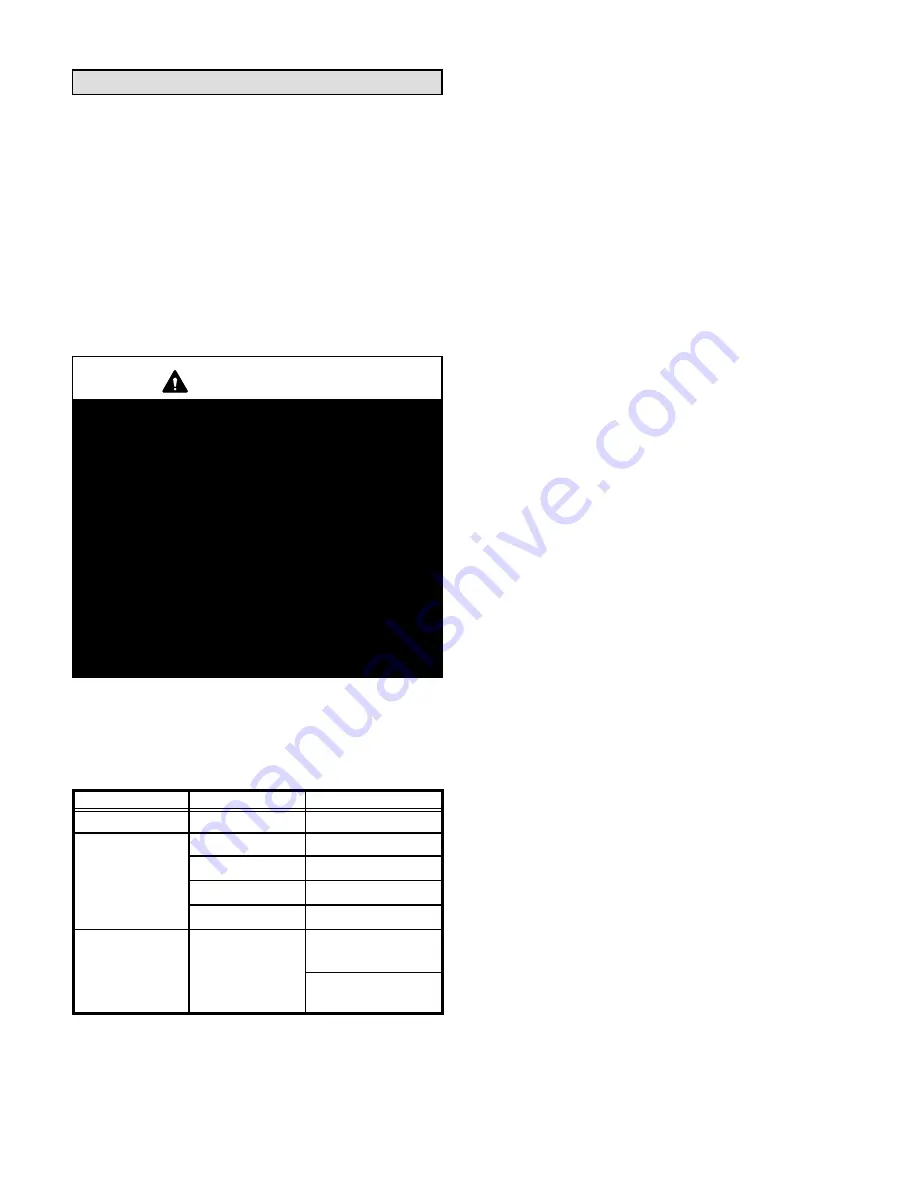

TABLE 1

Clearances

Location

Inches (mm)

Service access

Front

24 (610)

Side and rear

0 (0)

To combustible

Top

1 (25)

To combustible

materials

Flue

6 (152)*

Floor

0 (0)**

Around com

bustion cham

Front

B1Vent

3 (76)

bustion cham

ber air opening

Front

Single Wall Vent

4 (102)

NOTE-Service access clearance must be maintained.

* 1 inch (25mm) for type B1" Vent Pipe.

**For installation on combustible floors, appliance shall not be installed

directly on carpeting, tile, or other combustible material other than wood

flooring.

Vent installations must be in accordance with the pro

vided venting tables and applicable provisions of local

building codes.

For installation in a residential garage, the furnace must

be installed so that the burner(s) and the ignition source

are located no less than 18 inches (457 mm) above the

floor. The furnace must be located or protected to avoid

physical damage by vehicles. When a furnace is installed

in a public garage, hangar, or other building that has a

hazardous atmosphere, the furnace must be installed ac

cording to recommended good practice requirements

and current National Fuel Gas Code.

Unit must be adjusted to obtain a temperature rise within

the range specified on appliance rating plate.

G23(X) units must be installed so that electrical compo

nents are protected from water.

When the furnace is used with cooling units, it shall be

installed in parallel with, or on the upstream side of, cool

ing units to avoid condensation in the heating compart

ment. With a parallel flow arrangement, a damper (or

other means to control the flow of air) must adequately

prevent chilled air from entering the furnace. If the damp

er is manually operated, it must be equipped to prevent

operation of either the heating or the cooling unit, unless

it is in the full HEAT" or COOL" setting.

When installed, the furnace must be electrically

grounded according to local codes. In addition, in the

United States, installation must conform with the current

National Electric Code, ANSI/NFPA No. 70. The Nation

al Electric Code (ANSI/NFPA No. 70) is available from

the following address:

National Fire Protection Association

1 Battery March Park

Quincy, MA 02269

Field wiring connection with unit must meet or exceed

specifications of type T wire and withstand a 63

F (17

C)

temperature rise.

This furnace is designed for a minimum continuous return

air temperature of 60° dry bulb for cases in which a ther

mostat night setback is used. Return air temperature

must not exceed a maximum of 85

F db.

NOTE - G23(X) series units must not be used as a

construction heater during any phase of construction.

Very low return air temperatures, harmful vapors and

misplacement of the filters will damage the unit and low

er its efficiency.