TESTING HOSE LINES

Information on the service life of

L&W high pressure hoses

Version: 2020-06-01

Page - 4

Recurring test

Since hose lines are subject to influences that cause damage during operation and can lead

to dangerous situations, they must be tested recurrently at fixed intervals. The aim of recurring

tests is to detect and repair damage in good time.

The objective is to ensure that the system remains in a safe condition.

Procedure for hose lines found to be "defective"

If defects are found during the testing of the hose line that impair the safe condition of the work

equipment, these must be rectified immediately. If this is not possible, suitable measures must be

taken to ensure that the machine cannot be used further before it is repaired. Defective hose lines

must be replaced before the machine can be used further.

It is not permitted to repair or reassemble damaged hose lines with old, previously used parts!

If several hose lines are replaced at the same time, precautions must be taken to prevent mix-ups of the

connections or the installation points.

Test intervals

Deadlines for the recurring tests of the hose lines should already be set before commissioning.

Otherwise, there is a risk that work equipment will continue to be used or operated for too long without

being tested.

The intervals between the recurring tests must be selected in such a way that deviations from

the safe operating condition of work equipment can be detected and eliminated in good

time.

The intervals for recurring tests specified here are guidelines and based on experience. Shorter test

intervals may have to be specified on the basis of the risk assessment; special operating conditions; or

according to the manufacturer's specific instructions in the machine operating manual. Longer test

intervals may also be specified, provided that this is justifiable and tenable from a safety point of view.

The determination of the test intervals should be documented.

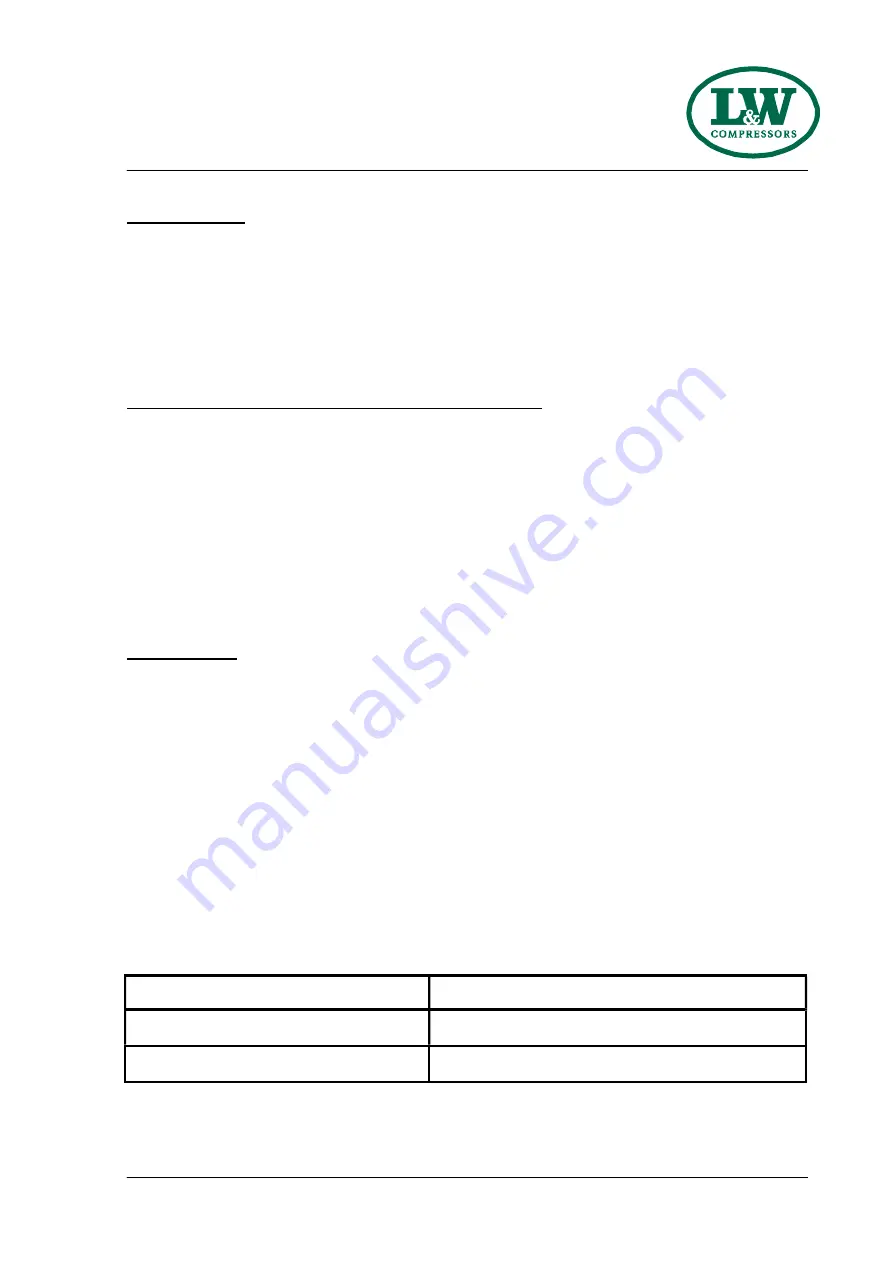

Type of test

Recommended test intervals

Visual inspection

Before commissioning the system

Functional test

Annually with previous visual inspection

Summary of Contents for LW 150 ES

Page 3: ...A Operating Instructions Breathing Air Compressor LW 150 ES LW 200 ES Version 31 01 2022...

Page 12: ...A S A F E T Y P R E C A U T I O N S...

Page 19: ...A I N S TA L L AT I O N...

Page 26: ...A O P E R AT I O N...

Page 34: ...A R E M E D Y I N G FA U LT S...

Page 39: ...A M A I N T E N A N C E A N D S E R V I C E...

Page 67: ...A M A I N T E N A N C E R E C O R D S...

Page 75: ...C ERSATZTEILLISTEN SPARE PARTS LISTS DETAILANSICHTEN DETAILED VIEWS...

Page 77: ...Inhaltsverzeichnis Kondensat Sammelbeh lter Condensate Catch Tank 46...

Page 125: ...D O P T I O N S...

Page 127: ...D A U T O S T A R T F U N C T I O N D 1 LW 150 200 ES...

Page 132: ...C A D D I T I O N A L F I L L I N G H O S E D 6 LW 150 200 ES...

Page 134: ...C Version 10 09 2021 A D D I T I O N A L F I L L I N G H O S E D 8 LW 150 200 ES...

Page 139: ...D I N T E R S TA G E P R E S S U R E G A U G E D 13 LW 150 200 ES...

Page 143: ...D O I L P U M P D 17 LW 150 200 ES...

Page 146: ...D Version 10 09 2021 Detailed View O I L P U M P D 20 LW 150 200 ES...

Page 147: ...D O I L P R E S S U R E G A U G E D 21 LW 150 200 ES...

Page 150: ...D O I L P R E S S U R E M O N I T O R I N G D 24 LW 150 200 ES...

Page 154: ...D O I L T E M P E R A T U R E M O N I T O R I N G D 28 LW 150 200 ES...

Page 157: ...D C Y L I N D E R H E A D T E M P E R AT U R E M O N I T O R I N G D 31 LW 150 200 ES...

Page 160: ...D F I N A L F I LT E R S E PA R A T O R 2 3 LT R D 34 LW 150 200 ES...

Page 167: ...C A D D I T I O N A L H I G H P R E S S U R E O U T L E T D 41 LW 150 200 ES...

Page 170: ...D A I R C O O L E R C O N N E C T I O N K I T D 44 LW 150 200 ES...

Page 173: ...E A T T A C H M E N T Version 11 12 E...

Page 177: ...INFORMATIONON THE SERVICE LIFE OF L W HIGH PRESSURE HOSES...

Page 185: ...ANNEX...