VARIABLY SPACED HALF-BLIND DOVETAILS

36

Chapter 10

D4R Pro User Guide

10-20

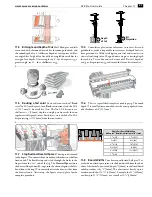

Remove the test tail board, then clamp a scrap board in

the front of the jig so that the top edge projects above the top face

of the jig by about

1

⁄

8

"[3mm]

➀

. This will keep the scrap piece

below the path of the bit when routing the pin board.

Remove the spacer board from the rear clamp.

1

10-21 If you’re mounting Thin Pin Boards:

The minimum recommended pin board thickness is

1

⁄

2

"[13mm]. If

you wish to rout a pin board less than the minimum thickness

➀

,

it will be necessary to pack the board up from the jig body. We

suggest using a piece of

1

⁄

4

" to

3

⁄

8

"[6 to 9mm] plywood for this

purpose

➁

.

2

1

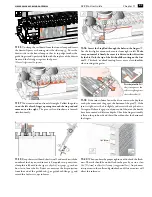

10-22 Flush Drawers

Place a test pin board in the left rear

clamp against the side stop, fitting its front end edge flush against

the vertical scrap piece, inside face

i

of the drawer front away from

the jig body. The pin board is now positioned with the edge to be

routed flush with the jig’s front face, correctly registered for the scale

readings.

For drawers with rabbeted fronts, see Chapter 12.

10-23

Rotate the finger assembly to the

h

HB PINS mode. Set

the HB PINS scale equal to tail board thickness (i.e., same setting as

tails: this example,

3

⁄

4

"[20mm]).

HB pins and HB tail scales are

always set to tail board thickness. Make sure the finger assembly

is flush and level on the pin board.

The guidefingers must touch

the pin board or depth of cut will vary, causing poor joint fit.

10-24

If you have difficulty leveling the finger assembly on a

narrow workpiece, place a board the same thickness as the pin

board under the other end of the finger assembly,

but not under

the rear clamp

.

Rout out the waste between the pins. Rout each

space from

left to right. Do not back rout on end

grain. If the bit enters on the right side of the opening there will

be a very strong pull to the left, so...

Rout each opening in at least

three or four passes,

left to right.

10-25

Summary of Contents for D4R Pro

Page 14: ...JIG ASSEMBLY MOUNTING AND USING THE CLAMPS 6 Chapter 1 D4R Pro User Guide ...

Page 24: ...WOOD PREPARATION 16 Chapter 6 D4R Pro User Guide ...

Page 86: ...BIT SELECTION 78 Appendix II D4R Pro User Guide ...

Page 90: ...JIG PARTS 82 Appendix III D4R Pro User Guide ...

Page 92: ...PRINTED IN CANADA Joining Tradition with Today Printed in Canada ...