H2-506 Vector Easy Servo Drive User Manual Version 1.0

Leadshine Technology Co., Ltd

11/F, Block A3, iPark, No.1001 Xueyuan Blvd. Shenzhen, China

Tel: 1-949-608-7270 Fax: 1-949-608-7298

Web

:

www.leadshine.com

Email:

response, pulse width should be longer than 2.5uS(200K bandwidth) or 1uS(500K

bandwidth)

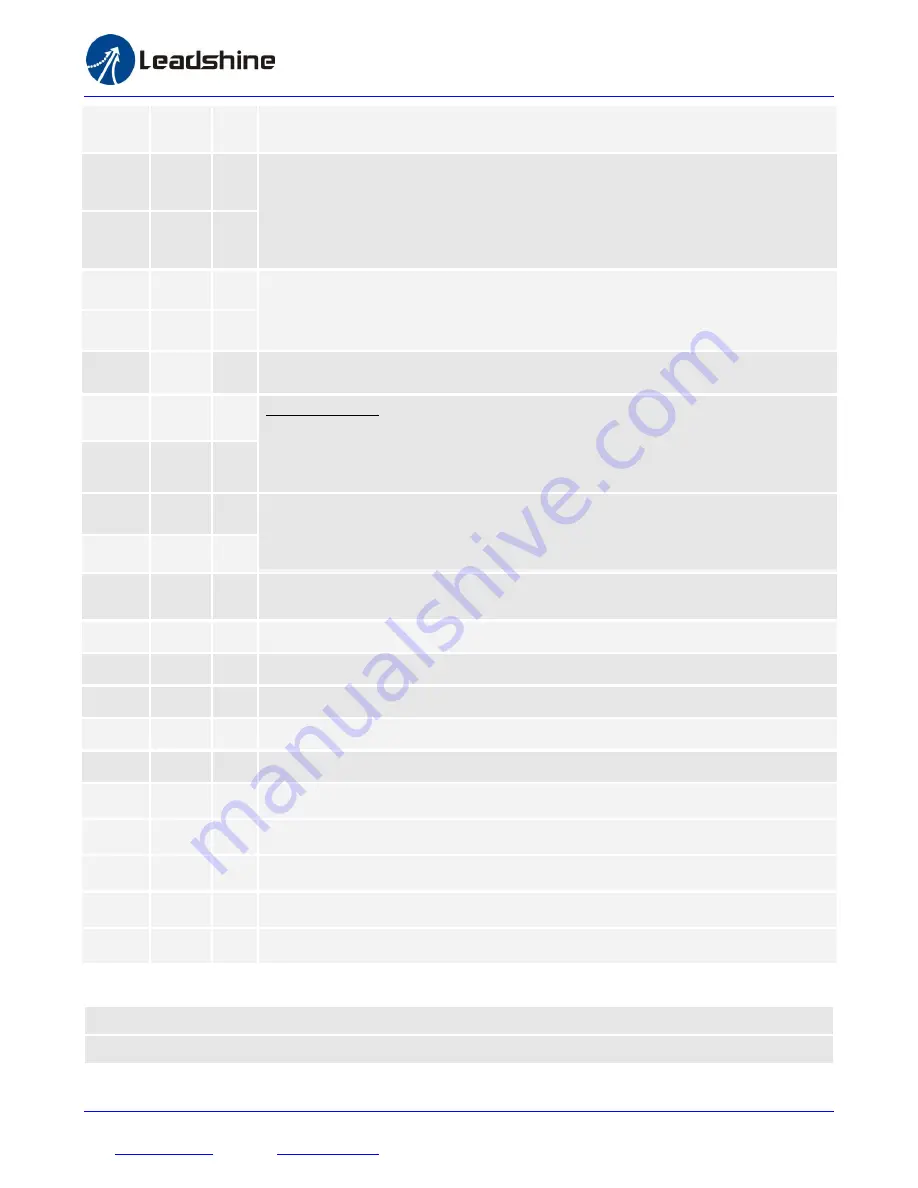

5

DIR+

I

Direction Signal: In single-pulse mode, this signal has low/high voltage levels,

representing two directions of motor rotation. In double-pulse mode (software

configurable), this signal is counter-clock (CCW) pulse, active both at high level and low

level. For reliable motion response, DIR signal should be ahead of PUL signal by 5μs at

least. 5-24V when DIR-HIGH, 0-0.5V when DIR-LOW. The direction signal’s polarity is

software configurable.

6

DIR-

I

7

NC

No connection.

8

NC

9

SGND

O

Signal GND

10

Pend+

O

In-position Signal: OC output signal, active when the difference between the actual

position and the command position is zero. This port can sink or source 20mA current at

24V. The resistance between Pend+ and Pend- is active at high impedance.

The signal also can be used for

brake output by setting parameter NO 30004 in

ProTuner.

11

Pend-

O

12

ALM+ O

Alarm Signal: OC (Open Collector) output signal, activated when one of the following

protection is activated: over-voltage, over current, braking error and position following

error. They can sink or source MAX 100mA current at 5V. The active impedance of

alarm signal is software configurable.

13

ALM-

O

14--16

NC

-

No connection.

17

FG

-

shield GND

18

SGND

Signal GND

19

+5V

I

5V+ input for encoder,50MA

20

AO+

O

Encoder A + output

21

AO-

O

Encoder A - output

22

BO+

O

Encoder B+ output

23

BO-

O

Encoder B- output

24

ZO+

O

Encoder Z+ output

25

ZO-

O

Encoder Z- output

26

SGND

Signal GND

3.2 Encoder Signal Input CN2

CN2 – Feedback Signal (Encoder) Connector

HDD15, 15Pin, Female