Software Control

4-10

D850R3

User’s Manual Switchos II

f)

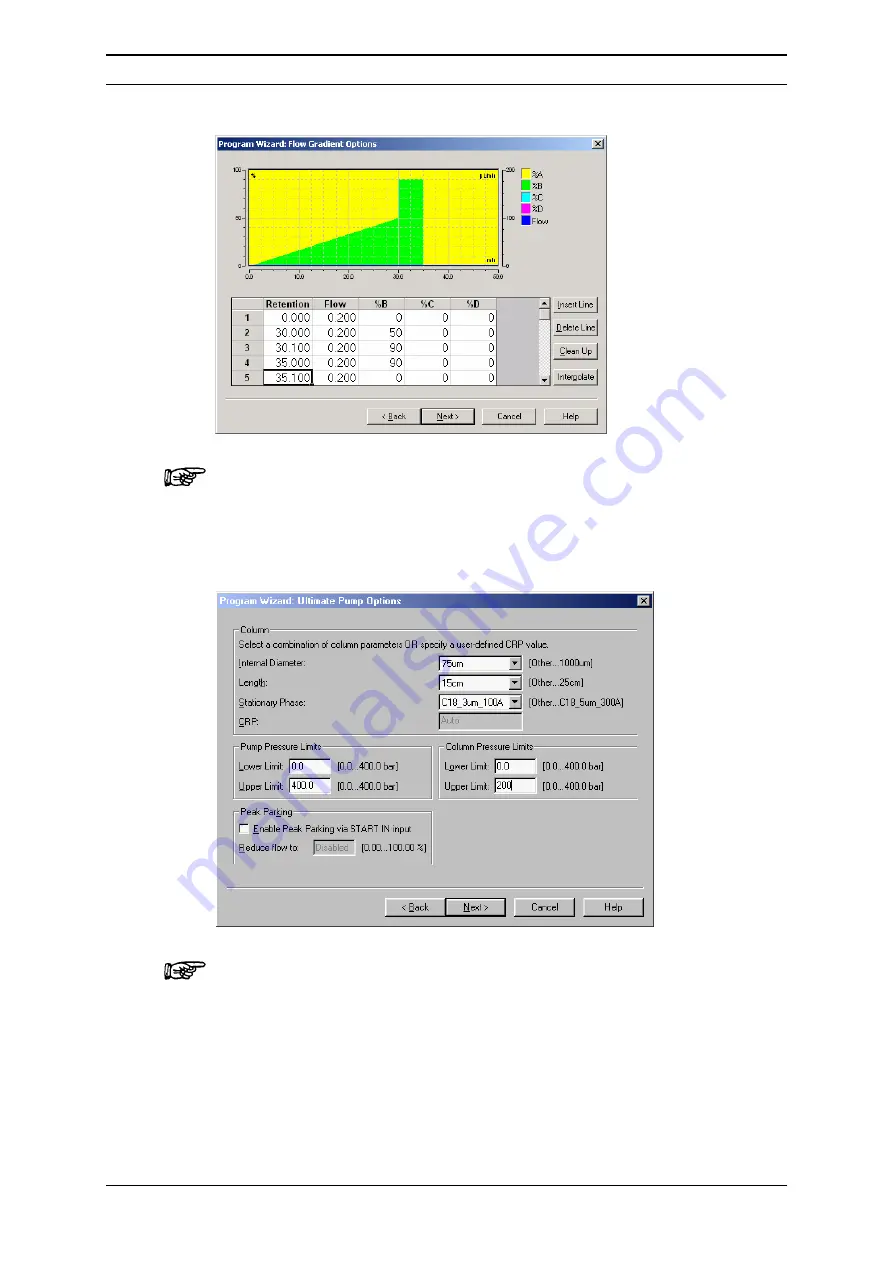

Define the gradient in the

Flow Gradient Options

FIGURE 4-10 The Flow Gradient Options Box

Note: The

Flow Gradient

box is not present if the ‘isocratic’ option was selected

in the

Pump Options

box in the previous step.

g)

Setup the pressure limits for the separation column and the UltiMate pump,

and define separation column parameters (e.g. I.D., length and stationary

phase) in the

UltiMate Pump Options

box (FIGURE 4-11).

FIGURE 4-11 The UltiMate Pump Options Box

Note: If you do not specify the ‘Column’ parameters (e.g. the option ‘other’ is

selected), you need to enter a CRP (Column Resistance Parameter) value. The

CRP is required to calculate the (master) flow rate of the UltiMate Micropump.

h)

Specify the detector settings (e.g. the data collection rate) in the

UV Options

box.

i)

Define the type of injection you want to use and the corresponding injection

parameters in the

Sampler Options

box.

Summary of Contents for SWITCHOS II

Page 6: ...Table of Contents iv D850R3 User s Manual Switchos II This page intentionally left blank...

Page 14: ...CE Declaration xii D850R3 User s Manual Switchos II This page intentionally left blank...

Page 22: ...Introduction 1 8 D850R3 User s Manual Switchos II This page intentionally left blank...

Page 80: ...The Switching Valves A 4 D850R3 User s Manual Switchos II This page intentionally left blank...

Page 82: ...Network Identification B 2 D850R3 User s Manual Switchos II This page intentionally left blank...