MAINTENANCE AND LUBRICATION

4-35

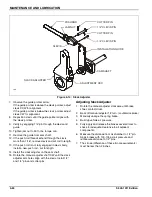

Crank Landing Gear

1.

The landing gear receives adequate lubrication

during manufacturing. Relubrication is possible

through grease fittings and is recommended at three

month intervals.

2.

The elevating screw is lubricated by the lower grease

fitting located on the upper housing

Prior to lubrication, extend the landing

gear as far as possible. During lubrication, slowly

retract the landing gear. The upper grease fitting

lubricates the gearing, shafts, and bushings. It is

recommended to use a high quality commercial

grade lithium EP-2 grease.

IMPORTANT

Shift crankshaft inward into high gear before

lubricating the upper grease fitting.

3.

When inspecting the landing gear, any parts which

are subjected to wear or damage, must be checked

and replaced if worn or damaged. The inspection

and maintenance intervals must be decreased if the

trailer is operated under arduous transport

conditions.

4.

Repair Instructions

a.

In order to repair landing gear, the legs should be

taken off the trailer by removing the mounting

attachment bolts and cross shaft.

b.

For two speed leg assembly, remove cover by

removing cover screws.

IMPORTANT

The cover is sealed to the upper housing with a

silicone sealant. When replacing the cover a suitable

silicone sealant must be used. Dow Corning #700 or

equal is recommended.

c.

Remove grease before disassembly. Drive spiral

pins from output spur gear and input gear.

d.

Then drive out output shaft by placing a punch

through hole in output spur gear and driving the

shaft out. Now both items can be removed.

e.

Remove cap plug. Shift input gear shaft to the

high gear position. Then drive out roll pin with a

3/8” diameter punch, by using the .50 diameter

hole at the side of the shaft in the outer housing.

IMPORTANT

For two speed leg assemblies without the side

access hole, use a curved 3/8” diameter punch.

f.

Remove output cluster shaft.

g.

Shift input gear shaft to the low gear position.

Position mark on end of input gear shaft in a

vertical position. Remove locknuts from shift

housing. Pull out the input gear shaft and shift

housing as one unit.

h.

Remove bevel gear and output cluster gear by

lifting upwards on both parts at the same time.

Remove groove pin and thrust washer. Lift outer

housing off from inner leg assembly.

i.

Remove thrust bearing and collar.

IMPORTANT

Thrust bearing must be exchanged complete with

collar. New thrust bearing must be packed with

grease before assembly.

IMPORTANT

If elevating screw shows sign of wear, replace lower

leg assembly before mounting. Make sure elevating

screw and nut are sufficiently greased. If grease is

required, coat the entire surface of the screw with a

min. of 4 oz. of grease.

j.

If bushings are worn, they must be removed and

replaced. Install bushings with a step driver and

punch.

k.

Assemble shift housing and ball detent to input

gear. Apply a thin film of lithium grease to the

inside of the bushing before assembly.

Reassemble by compressing balls and spring

into hole in input gear. Then slide shift housing

onto the shaft, capturing the detent balls and

spring.

Summary of Contents for 425B Series

Page 2: ......

Page 6: ...iv F 543 1011 Edition...

Page 14: ...2 6 F 543 1011 Edition STANDARD SPECIFICATIONS...

Page 26: ...3 12 F 543 1011 Edition OPERATING INSTRUCTIONS Figure 3 7 Steps for Loading and Unloading...

Page 32: ...3 18 F 543 1011 Edition OPERATING INSTRUCTIONS Figure 3 12 Dock Leveler Operation...

Page 61: ...MAINTENANCE AND LUBRICATION 4 21 Figure 4 13 Axle and Brake Assembly...

Page 76: ...4 36 F 543 1011 Edition MAINTENANCE AND LUBRICATION Page Intentionally Blank...

Page 86: ...5 10 F 543 1011 Edition TROUBLESHOOTING GUIDE...

Page 87: ......