4-6

F-543-1011 Edition

MAINTENANCE AND LUBRICATION

6.

Replace any missing or illegible decals. Replace any

missing or damaged reflective tape.

7.

Use Troubleshooting Guide to check for

“SYMPTOMS” AND “PROBLEMS” of any semitrailer

system not functioning correctly, or where wear,

distortion, or breakage can be found. Administer

“REMEDY” according to right-hand column of

Troubleshooting guide.

8.

After disassembling any components, thoroughly

clean dirt and old lubricant from all parts. Do not use

a wire brush on any bearing parts or surfaces — use

a stiff bristle brush. Do not use compressed air, or

spin bearing parts when cleaning. These practices

can throw solvents, dirt, or metal particles into your

eyes. Dry clean parts with lint free, clean, soft,

absorbent, cloth or paper. Wash and dry hands.

9.

Inspect seals, seal wiping surfaces, bearing caps,

and bearing cones for wear, pitting, chipping, or other

damage.

Gooseneck, Frame, and Deck

Repairing Structural Defects

If any structural defect is found, the fault must be

corrected before further use of the vehicle. To continue

usage could endanger the trailer, its load, personnel,

traffic, and properties. If any cracks or breaks are found,

contact the Landoll factory for repairs. Inspect the deck

daily for broken or missing planks or missing

attachments. Replace any defective parts promptly.

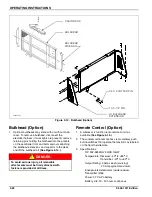

Fifth Wheel Latch Adjustment

1.

To adjust fifth wheel latch assembly, support fifth

wheel plate and adjust rear nut until the cam just

touches the flat surface on the latch

2.

Then tighten the front nut compressing the spring to

approximately 10-3/8” or until there is sufficient

tension to hold the fifth wheel plate in place.

IMPORTANT

To check the tension on the latch, place a pry bar

between the fifth wheel plate and the backing plate

and pry down until the latch release. If it releases too

easily, tighten the spring tension. If you are unable to

trip it, back off the spring tension until you are able to

trip the release.

WARNING

Figure 4-2: Fifth Wheel Latch Adjustment

1.

Too much tension will cause excessive wear

on the release and possibly bend the latch

rod.

2.

Stand clear of fifth wheel plate when prying it

down. Falling plate could cause serious

injury.

FIFTH WHEEL PLATE

FIFTH WHEEL LATCH CAM

HITCH SHIM

SPRING

HITCH PLATE BUSHING

1/4-28 GREASE FITTING

REAR HEX JAM NUT

FRONT HEX JAM NUT

LATCH ROD

m141609 op

Summary of Contents for 425B Series

Page 2: ......

Page 6: ...iv F 543 1011 Edition...

Page 14: ...2 6 F 543 1011 Edition STANDARD SPECIFICATIONS...

Page 26: ...3 12 F 543 1011 Edition OPERATING INSTRUCTIONS Figure 3 7 Steps for Loading and Unloading...

Page 32: ...3 18 F 543 1011 Edition OPERATING INSTRUCTIONS Figure 3 12 Dock Leveler Operation...

Page 61: ...MAINTENANCE AND LUBRICATION 4 21 Figure 4 13 Axle and Brake Assembly...

Page 76: ...4 36 F 543 1011 Edition MAINTENANCE AND LUBRICATION Page Intentionally Blank...

Page 86: ...5 10 F 543 1011 Edition TROUBLESHOOTING GUIDE...

Page 87: ......