MAINTENANCE AND LUBRICATION

4-33

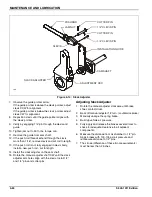

Dock Levelers

1.

Perform the following service procedure on a yearly

basis:

a.

Change oil with legs fully extended.

b.

After oil change, operate the dock leveler at least

three full cycles (complete leg strokes) to bleed

air from system.

c.

Fully extend legs. Clean extended legs. Coat

lightly with clean grease and grease alemite

fitting on each leg and check valve.

2.

Check all hydraulic lines and fittings for leaks and

worn spots. Replace any defective lines and fittings.

3.

Check for loose bolts and nuts.

Disassembly/Assembly Procedure

When disassembling and reassembling the leg, care

should be taken to keep all parts clean and to prevent

parts from being damaged. All seals should be coated

lightly with grease before reassembling the leg.

Leg

1.

To remove leg from trailer, make sure no weight is

being supported by legs. Have legs slightly extended

from full retract position to relieve any internal

pressure in legs. Disconnect the hoses from the leg.

You may wish to mark which hose goes to what port.

Remove the leg from the trailer.

2.

Remove the lock valve from the leg by screwing

counter clockwise

If you need

only to repair the lock valve, it may be removed from

leg while still on trailer if you have a minimum of 2”

clearance above.

3.

Remove o-rings and backup washers. Using a snap

ring pliers, remove snap ring. Loosen hex screw.

4.

Lift well tube off lower leg assembly. Lift piston rod to

gain access to top of cylinder head.

CAUTION

5.

Remove four hex screws. Lift cylinder head retainer.

A wire or rubber band may be used to hold cylinder

head retainer to sprocket near the top of piston rod

out of the way.

6.

Using a small flat screwdriver, carefully remove spiral

retaining ring. Lift piston rod assembly out of cylinder

tube.

7.

Using a large snap ring pliers, remove heavy duty

snap ring or remove the set screw. Remove the

piston, cylinder head, retaining ring, and cylinder

head retainer.

8.

Remove all seals and wear rings. Clean all parts.

Inspect all bearing surfaces for scratches, nicks, or

other defects; replace if necessary. Replace all wear

rings, and lightly lubricate all seals before installing

on legs.

9.

Carefully reassemble the leg in reverse order as

described above. Were applicable, torque piston to

40-50 ft.-lbs. Apply two drops of Loctite 277 or

equivalent to set screw and torque to 50 in./lbs.

Return leg to trailer and reconnect all hoses. Apply

grease to grease fittings and cycle legs fully several times

to bleed air from system. Check oil level.

Stabilizer Leg Check Valve

1.

Remove lock valve as described in

2.

Remove retaining plug

3.

Remove o-ring plug opposite retaining plug on

rectangular block.

4.

Using a drift small enough to fit through the port

opened in the previous step, tap out the lock valve

cartridges.

5.

Install new lock valve cartridges back to back (as

illustrated). Grease o-rings.

6.

Install two new o-rings and two back-up washers on

retaining plug.

7.

Thread retaining plug into body (tap gently to engage

threads). Torque plug to 15 ft.lbs.

8.

Install new o-ring on plug, opposite retaining plug.

Thread plug into body. Torque to 70 in.lbs.

9.

Replace spring and poppet. Replace the o-ring on

plug and reinstall.

10. Install new o-rings and back-up washers on top of

piston rod.

11. Thread lock valve on piston rod until firmly seated. If

the ports need to be relocated, loosen the screw at

the top of the well tube and turn lock valve clockwise

until ports are at the desired location. Retighten the

set screw.

While lifting piston rod, oil will squirt out of side

port at top of rod.

Summary of Contents for 425B Series

Page 2: ......

Page 6: ...iv F 543 1011 Edition...

Page 14: ...2 6 F 543 1011 Edition STANDARD SPECIFICATIONS...

Page 26: ...3 12 F 543 1011 Edition OPERATING INSTRUCTIONS Figure 3 7 Steps for Loading and Unloading...

Page 32: ...3 18 F 543 1011 Edition OPERATING INSTRUCTIONS Figure 3 12 Dock Leveler Operation...

Page 61: ...MAINTENANCE AND LUBRICATION 4 21 Figure 4 13 Axle and Brake Assembly...

Page 76: ...4 36 F 543 1011 Edition MAINTENANCE AND LUBRICATION Page Intentionally Blank...

Page 86: ...5 10 F 543 1011 Edition TROUBLESHOOTING GUIDE...

Page 87: ......