MAINTENANCE AND LUBRICATION

4-7

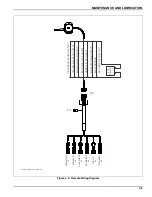

Hydraulic System

General

1.

Check the oil level of the tractor wet kit or hydraulic

engine power hydraulic tank weekly, or after any

leakage.

for proper hydraulic oil.

Check the hydraulic oil level with hydraulic cylinders

in the retracted position and the hydraulic pump

disengaged. Enough volume in tank (approximately

15 gallons) above hydraulic oil level must be available

to accept extra oil from cylinders when retracted.

2.

Overfilling can cause hydraulic fluid overflow during

operation.

3.

Dock leveler flow bypass regulator must provide 2.5

to 3.0 gallon per minute to dock leveler valve for

Single Pair Dock Leveler (62,000 lb.). Dock leveler

flow bypass regulator must provide 6.0 gallon per

minute to dock leveler valve for Double Pair Dock

Leveler (124,000 lb.).

4.

Hydraulic system pressure relief valves should be set

at 2500 psi.

Hydraulic Engine Package

1.

Check the hydraulic oil level weekly, or after any

leakage.

for proper hydraulic oil.

Check oil level with the undercarriage cylinders

extended and all other hydraulic cylinders in the

retracted position and with the engine stopped.

2.

Check hoses weekly for cracks or leaks. If a valve or

line leaks, it should be replaced immediately.

3.

Check the engine oil each time before using. Oil level

should be maintained between the “L” and “F” marks

on the oil dip stick. For further maintenance

procedures and proper lubrication specifications,

please refer to the engine owner’s manual that was

supplied with the hydraulic engine package.

4.

Replace hydraulic filter with new filter

5.

Use the fuel recommended for the engine package

installed on your semitrailer.

WARNING

If more oil than specified is sent to dock leveler

valve, damage to dock levelers and personal

injury can occur. If less oil than specified is sent

to dock leveler, they will not operate or operation

will be erratic.

Summary of Contents for 425B Series

Page 2: ......

Page 6: ...iv F 543 1011 Edition...

Page 14: ...2 6 F 543 1011 Edition STANDARD SPECIFICATIONS...

Page 26: ...3 12 F 543 1011 Edition OPERATING INSTRUCTIONS Figure 3 7 Steps for Loading and Unloading...

Page 32: ...3 18 F 543 1011 Edition OPERATING INSTRUCTIONS Figure 3 12 Dock Leveler Operation...

Page 61: ...MAINTENANCE AND LUBRICATION 4 21 Figure 4 13 Axle and Brake Assembly...

Page 76: ...4 36 F 543 1011 Edition MAINTENANCE AND LUBRICATION Page Intentionally Blank...

Page 86: ...5 10 F 543 1011 Edition TROUBLESHOOTING GUIDE...

Page 87: ......