5.

Install shoes, anchor pin bushings, anchor

pins, and spacers onto spider. Install

anchor lock rings.

IMPORTANT

ALWAYS USE ALL NEW SPRINGS WHEN

SERVICING BRAKES.

6.

Install brake return spring.

7.

Connect slack adjuster to brake chamber

pushrod.

8.

Adjust automatic slack adjuster as outlined

in

4-8.6

Automatic Slack Adjusters

The trailers automatic slack adjusters provide

the means for routine brake adjustment to compen-

sate for lining wear. Inspect slack adjusters every

2,000 miles to assure correct operation.

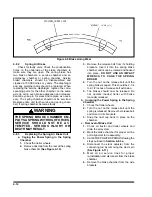

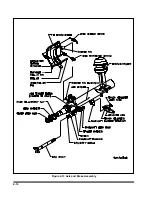

a. Operational Check (See Figure 4-11)

1.

Block wheels to prevent vehicle from

rolling.

2.

Check that the push rod is fully retracted,

apply air to release spring brake.

3.

Turn adjustment hex counterclockwise to

create an excessive clearance condition.

(A ratcheting sound will occur.)

4.

Make a full service brake application. On

release, allow sufficient time for brake to

fully retract. During the brake release,

observe rotation of the adjustment hex

(attach a wrench on the hex to make this

movement easier to see). This rotation

indicates that an excessive clearance

condition has been determined by the slack

adjuster, and it is making an adjustment to

compensate. On each subsequent brake

release the amount of adjustment and push

rod travel will be reduced until the desired

clearance is achieved

5.

The push rod stroke should be 1 1/2" to 2"

with an 100 to 105 PSI service brake

application.

6.

Measure the movement of the push rod

from the completely released position to

the applied position by marking the push

rod where it exits the air chamber before

and after application.

4-17

Figure 4-11 Slack Adjuster

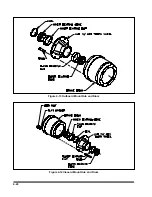

Summary of Contents for 345B

Page 3: ...MODEL 345B TRAILER OPERATOR S MANUAL PURCHASED FROM DATE ADDRESS PHONE NO SERIAL NO ...

Page 8: ......

Page 12: ......

Page 22: ...3 10 Figure 3 4 Steps for Loading and Unloading ...

Page 26: ...3 14 Figure 3 7 Rear Impact Guard and Antilock Brake System ...

Page 30: ......

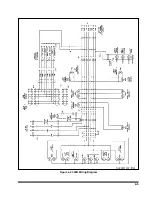

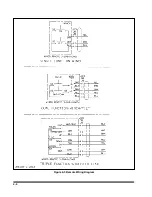

Page 35: ...4 5 Figure 4 2 345B Wiring Diagram ...

Page 36: ...4 6 Figure 4 3 Remote Wiring Diagram ...

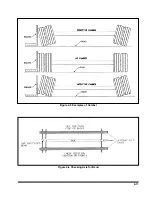

Page 41: ...4 11 Figure 4 5 Examples of Camber Figure 4 6 Checking Axle for Bend ...

Page 46: ...4 16 Figure 4 10 Axle and Brake Assembly ...

Page 50: ...4 20 Figure 4 13 Outboard Mount Hub and Drum Figure 4 14 Inboard Mount Hub and Drum ...

Page 54: ...4 24 Figure 4 18 Mounting Tires and Wheels Figure 4 19 Stud Tightening Sequence ...

Page 65: ...5 9 NOTES ...