2.

Align the front axle using the method

outlined in

3.

After proper alignment has been obtained,

tighten the suspension pivot bolt nut to the

torque listed in the table in

Section 4-6.2.

4.

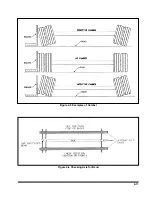

Align the rear axle to the front axle. Locate

the rear axle equalizer beam pivot bolt in

hanger at front end of driver’s side rear axle

equalizer beam. Loosen the suspension

pivot bolt lock nut. Rotate the head of the

pivot bolt. For axle alignment forward,

rotate bolt head clockwise. For axle

alignment rearward, rotate the bolt head

counter-clockwise. The rear axle should be

parallel with the front axle, with the

dimensions Y and Y1 being the same.

5.

Tighten the suspension pivot bolt nut to the

torque listed in the table in

Section 4-6.2.

c. Spring Suspension Axles

SPRING SUSPENSION TORQUE CHART

Size

1"

7/8"

7/8" U-

bolt

1/2"

Torque in

Ft.Lbs.

480-500

250

300

55-60

1.

Loosen the torque arm clamp bolts on the

adjustable torque arms and loosen the axle

U-bolts.

2.

Turn the adjustable torque arm on the front

axle until the proper alignment has been

achieved using the procedure outlined in

3.

Tighten the axle U-bolts to the torques

listed in the above table.

4.

Tighten the front axle torque arm clamp

bolts to the torque listed in the above table.

5.

Align the rear axle to the front axle in the

same manner using the torque arm for

adjusting. The rear axle should be parallel

with the front axle, with the dimensions Y

and Y1 being the same.

6.

Tighten the rear axle U-bolts to the torque

values listed in the above table.

7.

Tighten the rear axle torque arm clamp

bolts to the torque listed in the above table.

4-8 BRAKE SYSTEM MAINTENANCE

WARNING

USE GREAT CARE IF WHEELS OR

BRAKE DRUMS MUST BE HANDLED.

THEY MAY BE VERY HOT AND CAN

CAUSE SERIOUS INJURY.

4-8.1

General

.

a.

Check air hoses for chafing, bends, kinks, or

damaged fittings. Replace defective hoses.

b.

Check the brake system for loose, missing,

deformed, or corroded fasteners. Replace

and tighten defective hardware.

c.

Check brake linings for excessive wear or

distortion

(See Figure 4-9).

d.

Drain air reservoir daily. A drain cock on the

bottom of each air reservoir vents the tank to

drain collected water and oil. If held open, air

pressure in the tanks is relieved, causing the

emergency or parking brakes to be applied

(See Figure 4-8).

4-13

Figure 4-8 Drain Cock Locations

Summary of Contents for 345B

Page 3: ...MODEL 345B TRAILER OPERATOR S MANUAL PURCHASED FROM DATE ADDRESS PHONE NO SERIAL NO ...

Page 8: ......

Page 12: ......

Page 22: ...3 10 Figure 3 4 Steps for Loading and Unloading ...

Page 26: ...3 14 Figure 3 7 Rear Impact Guard and Antilock Brake System ...

Page 30: ......

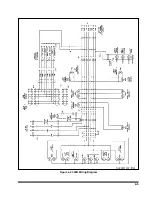

Page 35: ...4 5 Figure 4 2 345B Wiring Diagram ...

Page 36: ...4 6 Figure 4 3 Remote Wiring Diagram ...

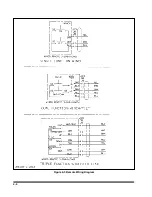

Page 41: ...4 11 Figure 4 5 Examples of Camber Figure 4 6 Checking Axle for Bend ...

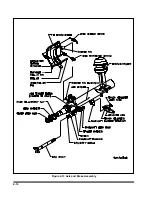

Page 46: ...4 16 Figure 4 10 Axle and Brake Assembly ...

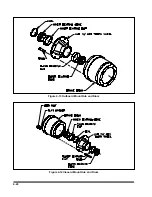

Page 50: ...4 20 Figure 4 13 Outboard Mount Hub and Drum Figure 4 14 Inboard Mount Hub and Drum ...

Page 54: ...4 24 Figure 4 18 Mounting Tires and Wheels Figure 4 19 Stud Tightening Sequence ...

Page 65: ...5 9 NOTES ...