PAGE 10

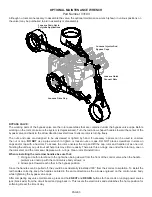

WATER METER AND METER PLUG

Item No.

Quantity

Part No.

Description

1

1

V3151

Nut 1” QC

2

1

V3003*

Meter Assy

3

1

V3118-01

Turbine Assy

4

1

V3105

O-Ring 215

5

1

V3003-01

Meter Plug Assy

*Part No. V3003 includes Items 2, 3 and 4

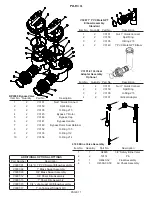

DRAIN LINE - 3/4”

Item No.

Quantity

Part No.

Description

1

1

H4615

Elbow Locking Clip

2

1

V3194

Polytube Insert 5/8

3

1

V3192

Nut for 3/4 Drain Elbow

4

1

V3158

3/4 Drain Elbow

5

1

V3163

O-Ring 019

6

1

V3159

DLFC Retainer

7

1

V3162-010 DLFC 1.0

7

1

V3162-017 DLFC 1.7

7

1

V3162-027 DLFC 2.7

7

1

V3162-032 DLFC 3.2

7

1

V3162-042 DLFC 4.2

BRINE REFILL

Item No.

Quantity

Part No.

Description

1

1

H4615

Elbow Locking Clip

2

1

H4614

Polytube Insert 3/8”

3

1

H4612

Nut 3/8”

4

1

H4613

Elbow Cap 3/8”

5

1

V3163

O-Ring 019

6

1

V3165

RFC Retainer Assy

7

1

V3182

RFC

*Part No. V3165 Includes Items 6 and 7

WS1 & WS1.25 Drawings & Service Manual

Page 17

Water Meter, Meter Plug and Mixing Valve

Drawing No.

Order No.

Description

Quantity

1

V3151

WS1 Nut 1” QC

1

2

V3003*

WS1 Meter ASY

1

3

V3118-01

WS1 Turbine ASY

1

4

V3105

0-ring 215

1

5

V3003-01

WS1 Meter Plug ASY

1

6

V3013

Mixing Valve

Optional

*Order number V3003 includes V3118-01 WS1 Turbine ASY and V3105 O-ring

215.

3

4

5

1

2

6

THIS WATER METER SHOULD NOT BE USED AS THE PRIMARY MONITORING DEVICE FOR CRITICAL HEALTH

EFFECT APPLICATIONS.

NOTE: A water meter is not applicable for a TC control valve.

WS1 & WS1.25 Drawings & Service Manual

Page 15

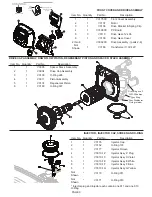

Drain Line – 3/4”

Water

Flow

Proper DLFC orientation

directs water ow towards

the washer face with

rounded edge.

Drawing No.

Order No.

Description

Quantity

1

H4615

Elbow Locking Clip

1

2

PKP10TS8-BULK

Polytube insert 5/8

Option

3

V3192

WS1 Nut ¾ Drain Elbow

Option

4*

V3158-01

WS1 Drain Elbow ¾ Male

1

5

V3163

O-ring 019

1

6*

V3159-01

WS1 DLFC Retainer ASY

1

7

V3162-007

WS1 DLFC 0.7 gpm for ¾

One DLFC

must be

used if ¾

tting is

used

V3162-010

WS1 DLFC 1.0 gpm for ¾

V3162-013

WS1 DLFC 1.3 gpm for ¾

V3162-017

WS1 DLFC 1.7 gpm for ¾

V3162-022

WS1 DLFC 2.2 gpm for ¾

V3162-027

WS1 DLFC 2.7 gpm for ¾

V3162-032

WS1 DLFC 3.2 gpm for ¾

V3162-042

WS1 DLFC 4.2 gpm for ¾

V3162-053

WS1 DLFC 5.3 gpm for ¾

V3162-065

WS1 DLFC 6.5 gpm for ¾

V3162-075

WS1 DLFC 7.5 gpm for ¾

V3162-090

WS1 DLFC 9.0 gpm for ¾

V3162-100

WS1 DLFC 10.0 gpm for ¾

Valves are shipped without drain line ow control (DLFC) - install DLFC before using. Valves

are shipped without ¾ nut for drain elbow (polytube installation only) and 5/8" polytube insert

(polytube installation only).

4

*4 and 6 can be ordered as a complete assembly - V3331 WS1 Drain Elbow and Retainer Asy

Page 14

WS1 & WS1.25 Drawings & Service Manual

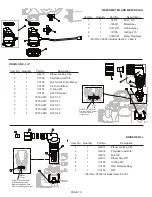

Refi ll Flow Control Assembly and Refi ll Port Plug

Water

Flow

Proper RFC orientation

directs re ll water ow

towards the washer face

with rounded edge and text.

Drawing No.

Order No.

Description

Quantity

1

V3195-01

WS1 Refi ll Port Plug Asy

This part is required for backwash only sys-

tems

2

H4615

Elbow Locking Clip

1

3

JCP-P-6

Polytube insert 3/8”

1

4

JCPG-6PBLK Nut 3/8”

1

5

H4613

Elbow Cap 3/8”

1

6

V3163

0-ring 019

1

7

V3165-01*

WS1 RFC Retainer Asy

1

8

V3182

WS1 RFC

1

9

V3330-01

WS1 Brine Elbow Asy w/RFC 3/8"

1

Not Shown

V3552

WS1 Brine Elbow Asy w/RFC 1/2"

Option

Not Shown

H4650

Elbow ½” with nut and insert

Option

*Assembly includes V3182 WS1 RFC.

9

2

3

7

4

5

6

1