1 About this operating manual

Issue EN 2022/05 PUK 6 Operating manual

8/56

1.3

Structure of the warnings

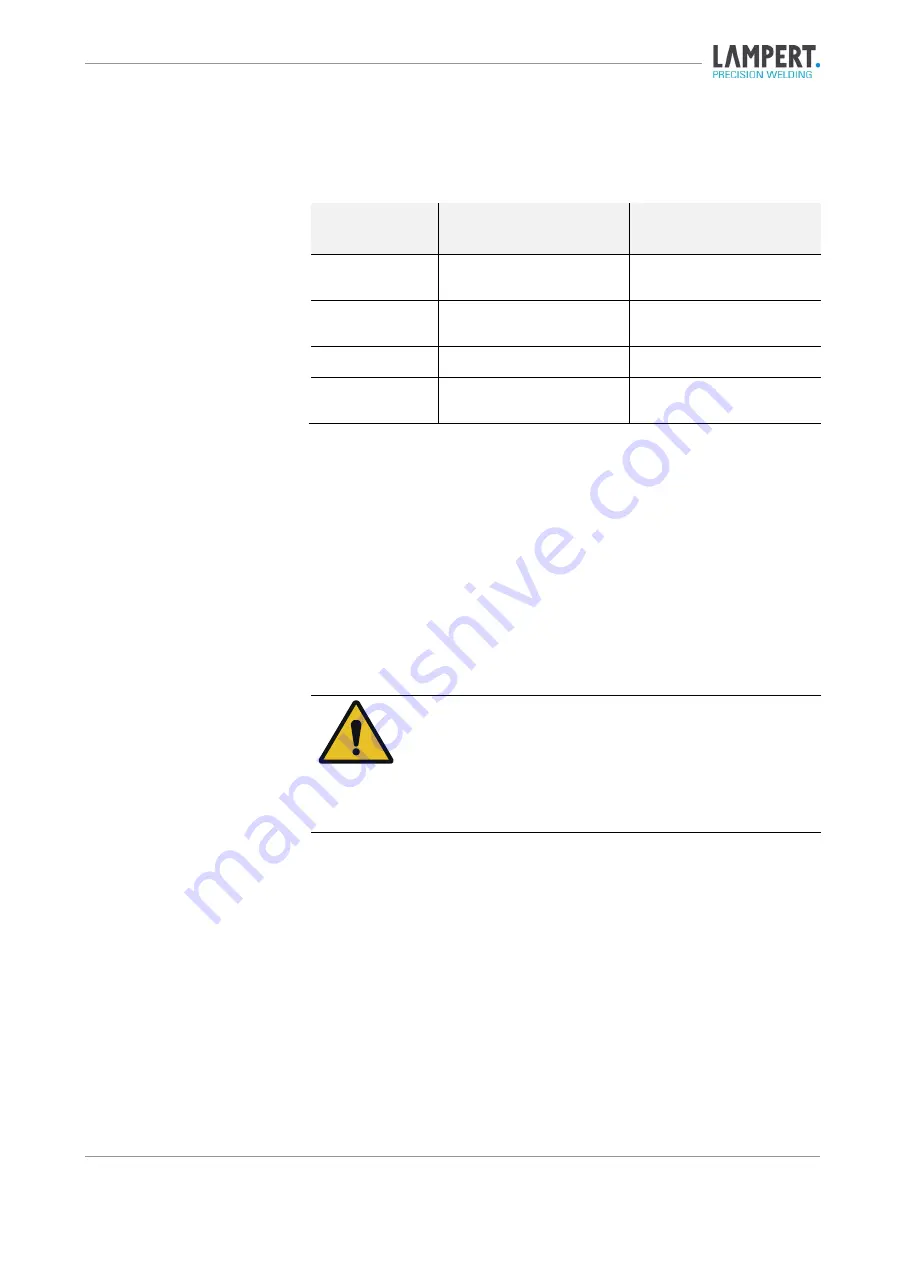

Signal word

Avoidance of ...

Possible consequences if

the warning is not heeded:

DANGER

Personal injury

(imminent danger)

Death or severe injuries!

WARNING

Personal injury

(potentially hazardous situation)

Death or severe injuries!

CAUTION

Personal injury

Light or minor injuries!

NOTE

Property damage

Damage to the device or its im-

mediate surroundings!

Tab. 1.1 Warning levels

The warnings are structured as follows:

•

Warning sign with signal word in accordance with the warning level

(see Tab 1.1)

•

Type of hazard (description of the hazard)

•

Consequences of the hazard (description of the consequences of the

hazard)

•

Hazard prevention (measures to prevent the hazard)

DANGER!

Type of hazard

Consequences of hazard

Hazard prevention