Manuel Technique OsmsoeurRO400C

Version 3

Page 8 / 26

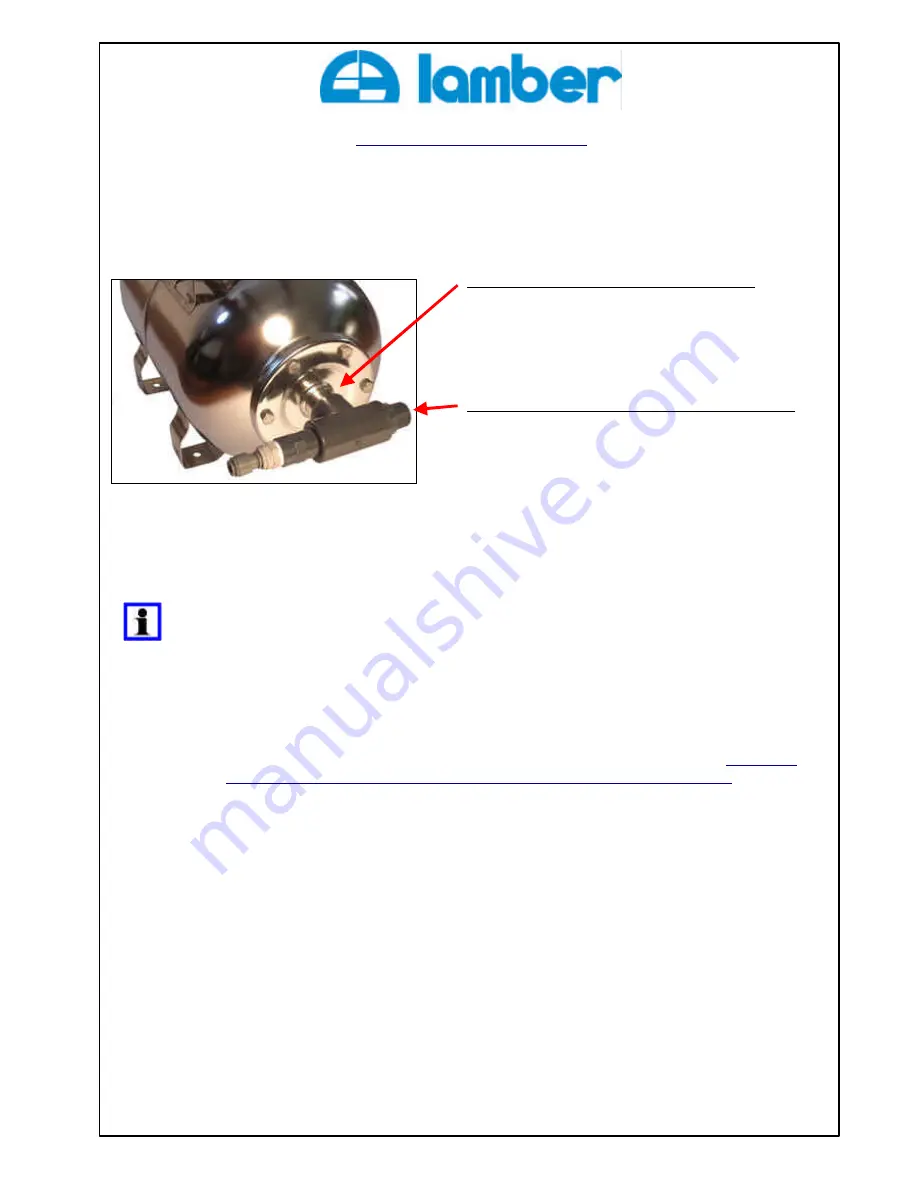

Storage tank connection

The explanation is here provided with a 20L stainless steel storage tank.

The assembly is the same for all models.

1. Screw the T with teflon on the outlet hose

2. Connect the flexible machine feed hose on the T.

Ø

Pressure tanks create a purified water stock always available and assure an optimal preservation

of the purified water quality, safe from ambient air.

Ø

The internal membrane ( pre-charged at 2,5 Bar) allows to return the under pressure stocked

water directly, without booster pump

Ø

They allow the RO400C to function on longer and less frequent cycles, so to have a water and

energy economy, a longer life of the parts that wear down and a better quality water.