Lake Shore Model 332 Temperature Controller User’s Manual

2.7 MANUAL

TUNING

There has been a lot written about tuning closed-loop control systems and specifically PID control

loops. This section does not attempt to compete with control theory experts. It describes a few basic

rules of thumb to help less experienced users get started. This technique will not solve every problem,

but it has worked for many others in the field. This section assumes the user has worked through the

operation sections of this manual, has a good temperature reading from the sensor chosen as a control

sensor, and is operating Loop 1. It is also a good idea to begin at the center of the temperature range of

the cooling system (not close to its highest or lowest temperature). AutoTune (Paragraph 2.8) is

another good place to begin, and do not forget the power of trial and error.

2.7.1 Setting

Heater

Range

Setting an appropriate heater output range is an important first part of the tuning process.

The heater

range should allow enough heater power to comfortably overcome the cooling power of the cooling

system

. If the heater range will not provide enough power, the load will not be able to reach the

setpoint temperature. If the range is set too high, the load may have very large temperature changes

that take a long time to settle out. Delicate loads can even be damaged by too much power.

Often there is little information on the cooling power of the cooling system at the desired setpoint. If

this is the case, try the following: Allow the load to cool completely with the heater off. Set manual

heater power output to 50% while in Open-loop control mode. Turn the heater to the lowest range and

write down the temperature rise (if any). Select the next highest heater range and continue the

process until the load warms up to room temperature. Do not leave the system unattended, the

heater may have to be turned off manually to prevent overheating. If the load never reaches room

temperature, some adjustment may be needed in heater resistance or load.

The list of heater range versus load temperature is a good reference for selection the proper heater

range. It is common for systems to require two or more heater ranges for good control over their full

temperature. Lower heater ranges are normally needed for lower temperature. The Model 332 is of

no use controlling at or below the temperature reached when the heater was off. Many systems can

be tuned to control within a degree or two above that temperature.

2.7.2 Tuning

Proportional

The proportional setting is so closely tied to heater range that they can be thought of as fine and

course adjustments of the same setting. An appropriate heater range must be known before moving

on to the proportional setting.

Begin this part of the tuning process by letting the cooling system cool and stabilize with the heater

off. Place the Model 332 in closed-loop control mode with manual PID tuning, then turn integral,

derivative and manual output settings off. Enter a setpoint several degrees above the cooling systems

lowest temperature. Enter a low proportional setting of approximately 5 or 10 and then enter the

appropriate heater range as described above. The heater display should show a value greater than

zero and less than 100%. The load temperature should stabilize at a temperature below the setpoint.

If the load temperature and heater meter swing rapidly, the heater range may be set too high and

should be reduced. Very slow changes in load temperature that could be described as drifting are an

indication of a proportional setting that is too low (which is addressed in the next step).

Gradually increase the proportional setting by doubling it each time. At each new setting, allow time

for the temperature of the load to stabilize. As the proportional setting is increased, there should be a

setting in which the load temperature begins a sustained and predictable oscillation rising and falling

in a consistent period of time. See Figure 2-3(a). The goal is to find the proportional value in which

the oscillation begins, do not turn the setting so high that temperature and heater output changes

become violent.

Record the proportional setting and the amount of time it takes for the load change from one

temperature peak to the next. The time is called the oscillation period of the load. It helps describe the

dominant time constant of the load which is used in setting integral. If all has gone well,

the

proportional setting is

one half

of the value required for sustained oscillation. See Figure 2-3(b).

2-12

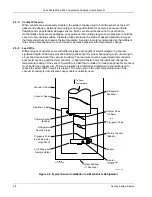

Cooling System Design