Lake Shore Model 332 Temperature Controller User’s Manual

2.3.7 Lead

Soldering

When additional wire is soldered to short sensor leads, care must be taken not to overheat the

sensor. A heat sink such as a metal wire clamp or alligator clip will heat sink the leads and protect the

sensor. Leads should be tinned before bonding to reduce the time that heat is applied to the sensor

lead. Solder flux should be cleaned after soldering to prevent corrosion.

2.3.8

Heat Sinking Leads

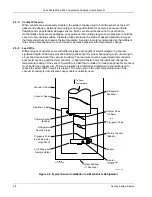

Sensor leads can be a significant source of error if they are not properly heat sinked. Heat will

transfer down even small leads and alter the sensor reading. The goal of heat sinking is to cool the

leads to a temperature as close to the sensor as possible. This can be accomplished by putting a

significant length of lead wire in thermal contact with every cooled surface between room temperature

and the sensor. Lead wires can be adhered to cold surfaces with varnish over a thin insulator like

cigarette paper. They can also be wound on a bobbin that is firmly attached to the cold surface. Some

sensor packages include a heat sink bobbin and wrapped lead wires to simplify heat sinking.

2.3.9 Thermal

Radiation

Thermal (black body) radiation is one of the ways heat is transferred. Warm surfaces radiate heat to

cold surfaces even through a vacuum. The difference in temperature between the surfaces is one

thing that determines how much heat is transferred. Thermal radiation causes thermal gradients and

reduces measurement accuracy. Many cooling systems include a radiation shield. The purpose of the

shield is to surround the load, sample, and sensor with a surface that is at or near their temperature

to minimize radiation. The shield is exposed to the room temperature surface of the vacuum shroud

on its outer surface, so some cooling power must be directed to the shield to keep it near the load

temperature. If the cooling system does not include an integrated radiation shield (or one cannot be

easily made), one alternative is to wrap several layers of super-insulation (aluminized Mylar) loosely

between the vacuum shroud and load. This reduces radiation transfer to the sample space.

2.4

HEATER SELECTION AND INSTALLATION

There is a variety of resistive heaters that can be used as the controlled heating source for temperature

control. The mostly metal alloys like nichrome are usually wire or foil. Shapes and sizes vary to permit

installation into different systems.

2.4.1

Heater Resistance and Power

Cryogenic cooling systems have a wide range of cooling power. The resistive heater must be able to

provide sufficient heating power to warm the system. The Model 332 can supply up to 50 W of power

to a heater (if the heater resistance is appropriate). The Model 332 heater output current source has a

maximum output of 1 A, limiting maximum power to:

Max Power (watts) = (1 ampere)

2

× Resistance (ohms).

Even though the Model 332 output is a current source, it has a voltage limit (called the compliance

voltage) of 50 V, which also limits maximum power:

Max Power (watts)

(50 volts)

Resistance (ohms)

2

=

.

Both limits are in place at the same time, so the smallest of the two computations gives the maximum

power available to the heater. A heater of 50

Ω

allows the instrument to provide its maximum power

of 50 watts. A typical smaller resistance of 25

Ω

allows 25 watts of power, while a typical larger

resistance of 100

Ω

is limited by compliance voltage to 25 watts. The resistor chosen as a heater

must be able to withstand the power being dissipated in it. Pre-packaged resistors have a power

specification that is usually given for the resistor in free air. This power may need to be derated if

used in a vacuum where convection cooling can not take place and it is not adequately heat sinked to

a cooled surface.

Cooling System Design

2-7