26

8. Disruptions

Disruption in Operation

The most common reason for disruption in operation of the unit is improper maintenance.

Maintenance should be carried out regularly according to the intervals defined on page

In case of disruption start with checking the following:

Fan polluted or blocked?

Coolant polluted?

Low coolant contents because of leakage, evaporation or an extended cooling circuit with long

hoses?

More help can be found in the following paragraph.

In case you do not succeed in identifying the problem cause by means of this manual please contact

the service department of Laird Thermal Systems.

Trouble Shooting

For trouble shooting you may rely on the following:

Alarm signaling within the safety circuit of the device to be cooled

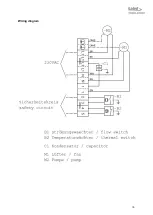

Wiring diagram

Flow scheme

Trouble shooting table given below

Problem

Possible reason

Countermeasure

The unit does not

start

Electrical connection not correct

or no mains connection

Check connection, insert mains plug, check main

power switch

The unit is

running, but

cooling capacity is

not available or

too low

External hoses sharply bent?

Pay attention to smooth bends, when hoses are

connected

Unit properly located?

Clearance to walls not less than 0.5 m

Is there flow in cooling circuit?

Flow is signaled potential-free by the safety

equipment of the unit and can be visualized in

the range of controls of the device to be cooled.

Contents in coolant container low Check coolant level, refill coolant if

necessary →

page 22

Fan turning?

Cover the ventilation grid next to the fan with a

sheet of paper. If the paper is sucked and hold

by the airflow, the fan works properly.

Ambient temperature too high?

Check specifications → page

Noisy unit

Contents in coolant container low Refill coolant

10. Trouble shooting list

Summary of Contents for WL3004

Page 1: ...WL3004 Liquid to Air Cooling System Specification and User Manual Version 1 2 ...

Page 35: ...35 Addendum Flow scheme ...

Page 36: ...36 Wiring diagram ...

Page 37: ...37 ...