28

Troubleshooting

Any operating problems with the SuperBrush

will likely occur most often during the period that

you are becoming familiar with its components and

their adjustments. If you are experiencing a problem

affecting the

machine’s

brushing performance,

check the following listings for potential causes

and solutions; it may also pay to review the

previous sections in this manual on setting up and

operating your machine.

Troubleshooting Guide: Motors

P

ROBLEM

P

OSSIBLE

C

AUSE

S

OLUTION

Motors do not start.

1.

Main power cord

unplugged from receptacle.

Plug in primary power cord.

2.

Brush motor cord

unplugged from receptacle

near power-feed motor.

Plug in brush motor and inverter

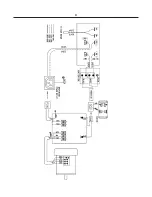

cord at receptacle on

machine if so equipped (Fig. 5).

3.

Circuit fuse blown or circuit

breaker tripped.

Replace fuse or retrip

breaker (after determining cause).

Brush motor overloads.

1.

Inadequate circuit.

Check electrical requirements

2.

Machine overloaded.

Use slower feed rate; slower brush

RPM; reduce depth of cut.

Conveyor

motor oscillates.

1.

Motor not properly

aligned.

Loosen housing bolts,

run motor, retighten bolts.

2.

Shaft collar or bushing worn.

Replace shaft collar or bushing

3.

Drive roller bent.

Replace drive roller

Brush motor or conveyor

gear motor stalls.

1.

Excessive depth of cut.

Reduce depth of cut; decrease

brush speed; reduce feed rate.

Summary of Contents for SuperMax 19-38 Combo

Page 1: ...19 38 Combo Brush Drum Sander Owner s Manual Lagunatools com SKU 219383...

Page 31: ...31...

Page 34: ...34 34...

Page 36: ...36...

Page 39: ...39...