6. Application Example

67

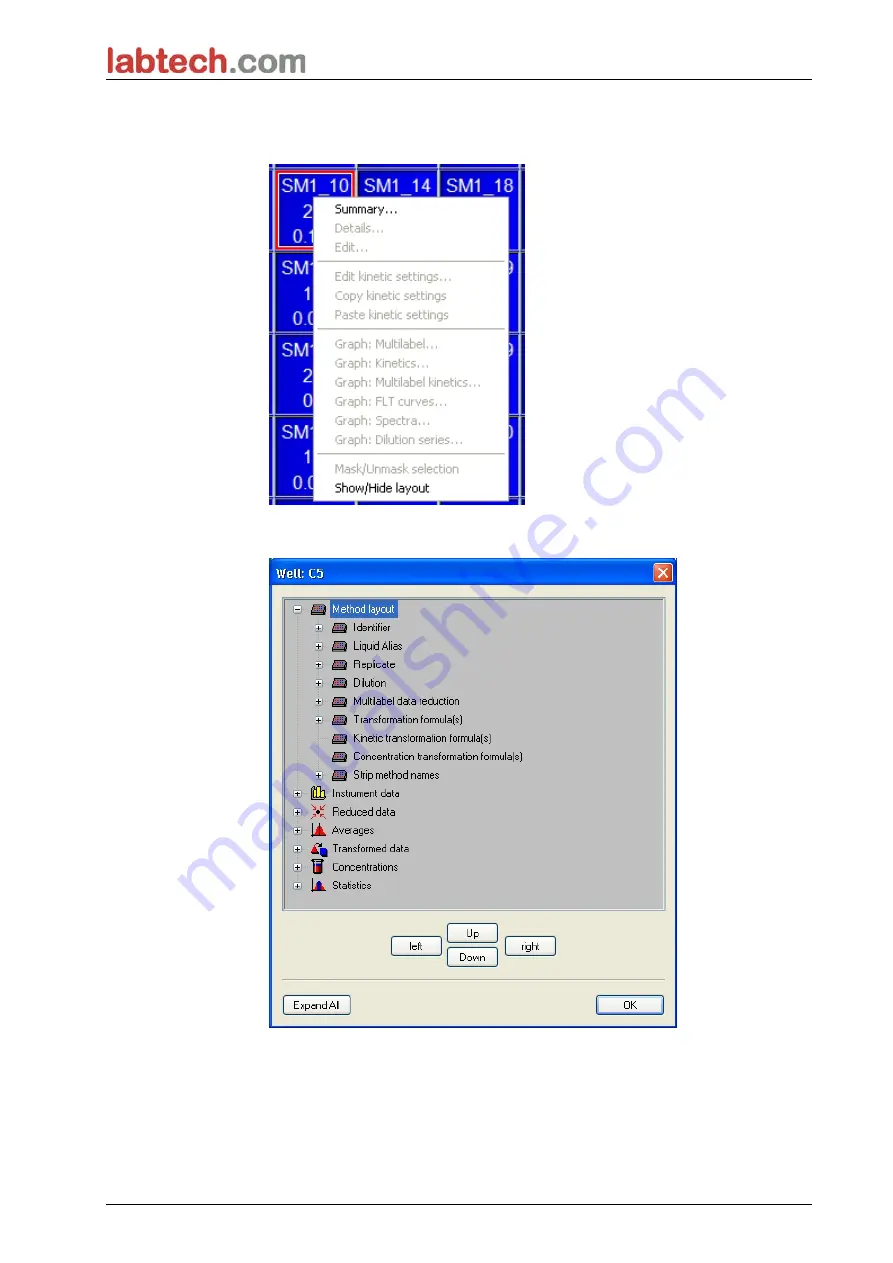

Click in the well with the right mouse key and the context-sensitive menu

appears:

Selecting

Summary

the following window is displayed providing detailed

information of the definition and the settings of the chosen well:

Click

Next

in the plate layout window and the

Save as

dialog box appears, where

you can enter a file name and remarks. Click the small

Save

button on the left of

the window to save the file; you can continue working on the method or

workspace. Click the

Finish

button on the right side at the bottom of the screen to

save the file and to close the wizard. The program goes back to the wizard list.