Page 15

b.

Drinking of alcoholic beverages

before or during spa or hot tub use can

cause drowsiness which could lead to

unconsciousness and subsequently result in

drowning.

c.

Pregnant women beware! Soaking in water

above 102°F (39°C) can cause fetal damage

during the first three months of pregnancy

(resulting in the birth of a brain-damaged or

deformed child). Pregnant women should

stick to the 100°F (38°C) maximum rule.

d.

Before entering the spa or hot tub, users

should check the water temperature with

an accurate thermometer; spa or hot tub

thermostats may err in regulating water

temperatures by as much as four degrees

Fahrenheit (2.2°C).

e.

Persons with a medical history of heart

disease, circulatory problems, diabetes or

blood pressure problems should obtain their

physician's advice before using spas or hot

tubs.

f.

Persons taking medications which

induce drowsiness, such as tranquilizers,

antihistamines or anticoagulants, should not

use spas or hot tubs.

SECTION 4.

Maintenance

1. Inspect the pump seal every 6 months. Replace the

pump if the seal shows signs of leakage or wear.

2. At start-up and every six (6) months thereafter, the

pilot and main burner flame should be observed

for proper performance (see Figure 16). See

attached lighting and shut-down instructions

for proper pilot flame pattern. If flame has the

appearance of "sooting" tips, check for debris near

orifices and call a qualified service technician.

3. Inspect the venting system for obstruction, leakage

and corrosion at least once each year.

4. Keep heater area clear and free from combustible

material, gasoline and other flammable vapors and

liquids (see Table 1 for minimum clearances).

5. Be certain all combustion air and ventilation

openings in the room are unobstructed.

6. Check for fouling on the external surfaces of

the heat exchanger every six months. (

NOTE:

after installation and first start-up, check the heat

exchanger for fouling after the following periods

of operation: 24 hours, 7 days, 30 days, 90 days

and once every six months thereafter.)

Fouling on the external surfaces of the heat

exchanger is caused by incomplete combustion

and is a sign of combustion air and/or venting

problems. As soon as any fouling is observed,

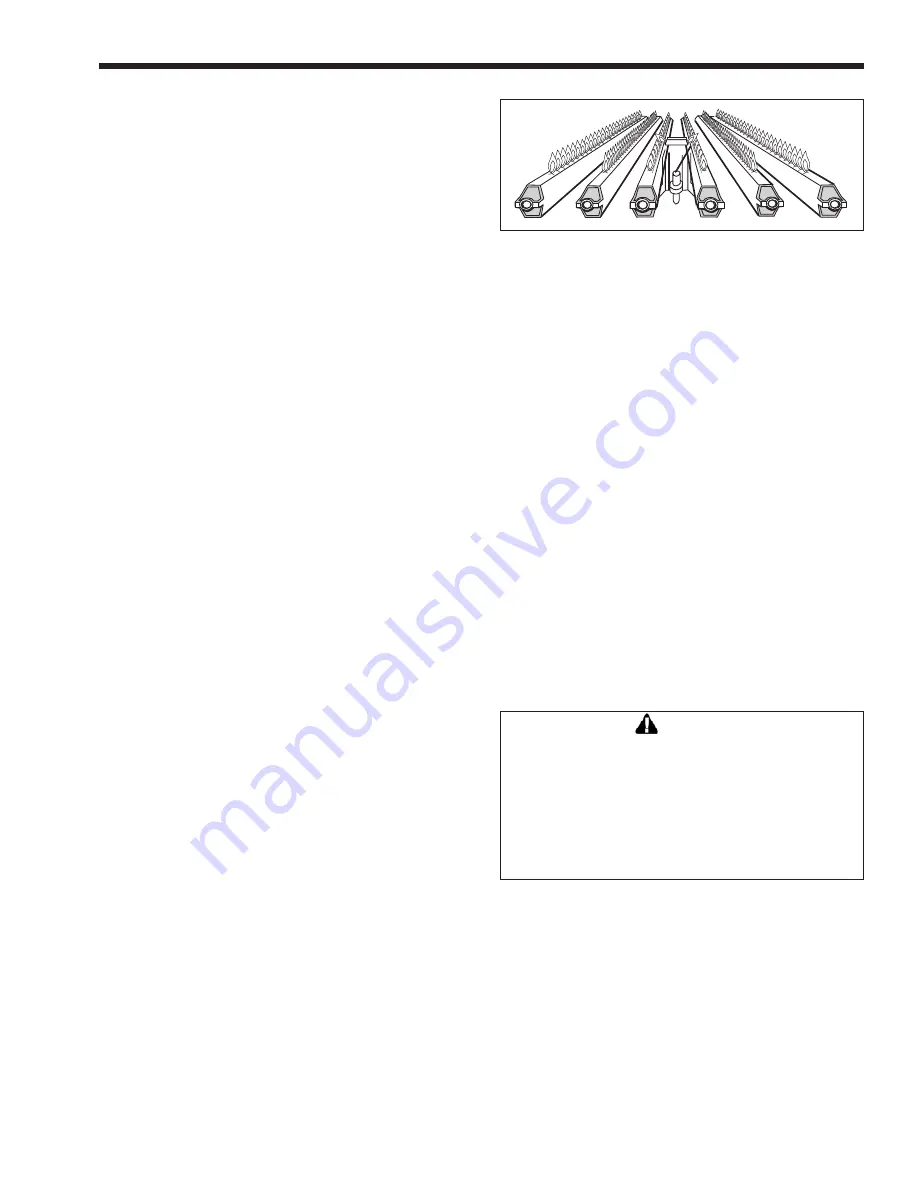

Figure 16. Main Burner Flame Pattern.

the cause of the fouling should be corrected (see

Section 5, Troubleshooting Guide). The heat

exchanger can be checked with a flashlight by

locating a mirror under the burners. An alternate

method is to remove the venting and top panels

as necessary to inspect the heat exchanger from

above. Also check the vent system for defects

at this time. (If cleaning is required, shut off all

electrical and gas supply to the heater.)

7. To expose the heat exchanger:

Indoor Models:

Remove the flue pipe, top of unit,

rear upper jacket, flue collector rear panel and heat

exchanger baffles.

Outdoor Models:

Remove vent top assembly,

rear upper jacket, flue collector rear panel and heat

exchanger baffles.

8. To remove all burners:

It is usually more convenient to remove the burner

tray assembly. Disconnect sensor wire, ignition

cable (or thermocouple generator) and pilot gas

line. Disconnect manifold inlet union(s). Remove

the four (4) retaining screws. Grasp the manifold

pipe and slide out the burner tray.

Caution

Black carbon or green soot on a dirty heat

exchanger can, under certain conditions, be

ignited by a random spark or open flame. To

prevent this unlikely occurrence, dampen the

soot deposits with wet brush or fine water

spray before servicing or cleaning the heat

exchanger.

9. Clean heat exchanger using a wire brush to

remove soot and loose scale from the unit. Clean

fallen debris from bottom of heater. Make sure

burner ports are clear and pilot assembly is free of

debris.

10. Reassemble in reverse order and be sure the heat

exchanger baffles are replaced.

11. The gas and electric controls installed on the

heater are engineered for both dependable

operation and long life, but the proper

functioning of these components is necessary

for safe operation of the heater. It is strongly

recommended that the basic items be checked by

a competent serviceman every year and replaced

MightyTherm Pool Heater