Page 10

The well should be installed just downstream

of the heater outlet tee. DO NOT INSTALL the

bulb in the heater loop piping or upstream of the

heater outlet tee.

5.

Route the capillary tube in a location where it will

not be subject to damage. Secure with wire ties.

2.9 Automatic Chlorinators

A concentration of chlorine in the heater can be

very destructive, therefor the following rules about

the installation and operation of such devices must be

followed:

1.

The chlorinator should be installed so it

introduces the gas or solution downstream from

the heater.

2.

The chlorinator should be wired so it cannot

operate unless the filter pump is running.

3.

The chlorinator should be provided with an anti-

siphon device so that the draining of the piping

after the pump shuts off will not siphon chlorine

solution into the heater.

4.

When the operation of a chlorinator is such

that it must be installed in the pump suction, or

some other place where the chlorine solution

flows through the heater, corrosion of the heater

can occur. Excessive concentrations of chlorine

caused by improper adjustment or failure of the

chlorination equipment cause this corrosion. The

resulting damage to the heat exchanger is not

covered by heater warranty.

SECTION 3.

Operation

3.1 Controls - General

(see Figures 11 and 12)

1. Electronic Ignition Controls:

a. Intermittent Ignition:

Pilots are automatically lit when the

operating control calls for heat (Systems

#4, #9 and #11). The unit performs its own

safety check and opens the main valves

only after the pilot is proven to be lit.

Whenever the pilot flame is interrupted, the

main gas valve closes within 0.8 seconds.

b.

Electronically Supervised Standing Pilot

System (System #16):

When pilot flame fails, the ignition control

module responds in less than 0.8 seconds

and provides 100% safety shutdown.

2. Operating Controls:

An electronic temperature control is provided

Heater Model

Minimum Filter Pump Flow Rate

500-850

90 GPM

1010 -1200

110 GPM

1430

140 GPM

1670-1825

180 GPM

Table 4. Minimum Flow to Supply Heater Loop.

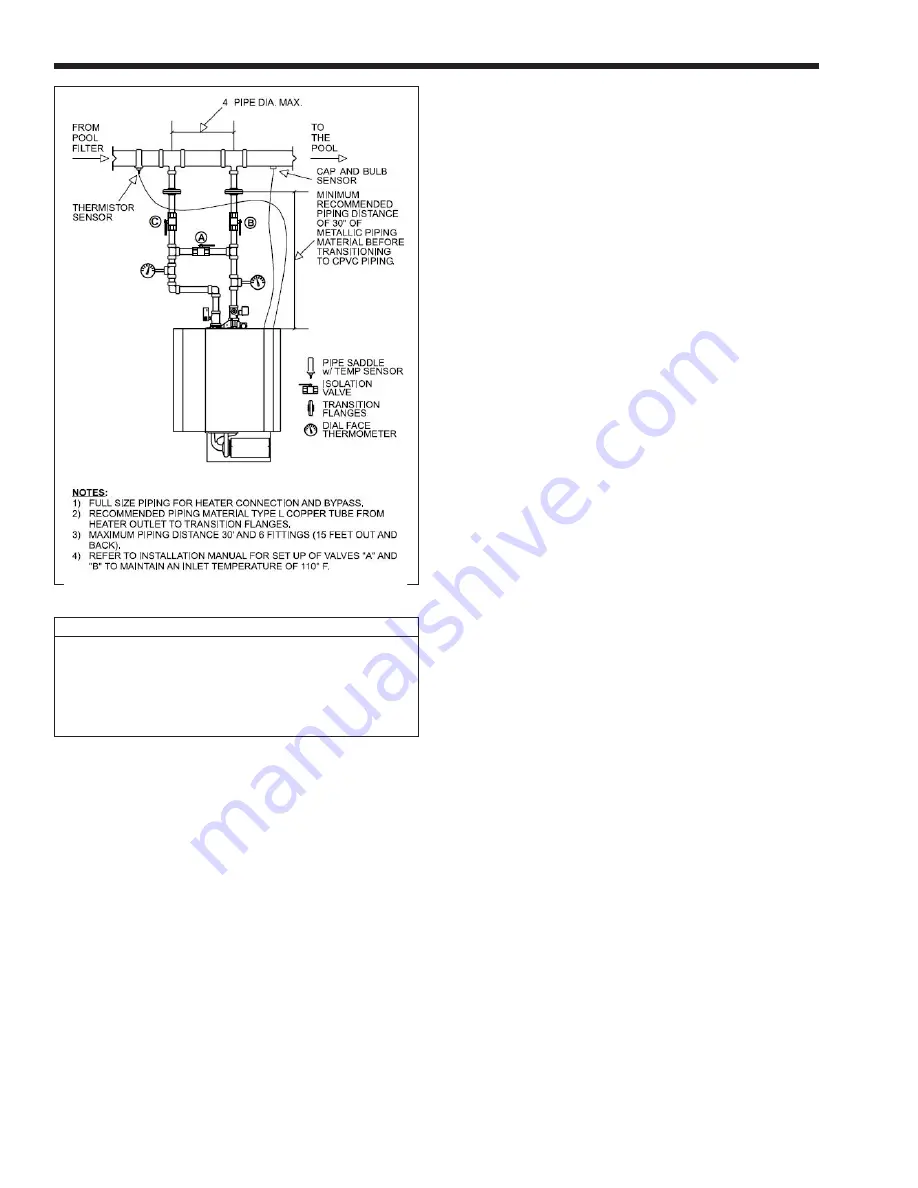

2.8 Temperature Sensor Placement

and Installation

Two temperature sensing devices are installed on the

heater that require sensing bulbs be field installed

according to Figure 10.

1.

Install the thermistor based sensor's immersion

well on the underside of the pool loop piping.

The well should be installed just upstream of

the heater inlet tee. DO NOT INSTALL the bulb

in the heater loop piping or down stream of the

heater outlet tee.

2.

Thread the spring and retainer onto the sensor

cable and secure sensor into the immersion well.

3.

Route cable to heater control panel in a location

where it will not be subject to damage. Secure

with nylon cable ties.

4.

Install the capillary tube/bulb sensor immersion

well on the underside of the pool loop piping.

Figure 10. Heater Piping Arrangement.

LAARS Heating Systems