35

Low Profile Side Wall Termination Kit

The IPEX Low Profile side wall termination kits are fully certified for use with IPEX product only. IPEX System 636

PVC Low Profile vent kits are made from certified compound and IPEX System 1738 PVC Low Profile vent kits

are made from a UL1738 certified PVC compound. Both are rated to a maximum temperature of 149°F

(65°C)

.

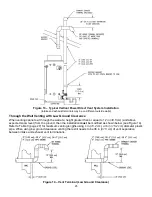

The vent termination

must

maintain all termination clearances and be installed in accordance with local

building codes and/or The National Fuel Gas Code ANSI Z223.1 (Latest Edition) or CGA/CAN B149

Installation Code (see Figure 25).

Each kit contains: 1 Base (two holes), 1 Cap (one hole), 8 Stainless Steel Screws, and 4 Plastic Anchors.

Table 5

– Approved IPEX Low Profile Terminals

Description

Pipe O.D.

Hole

Spacing

(ctr to ctr)

IPEX System

(1738 or 636)

IPEX Part

Number

3” Low Profile

3.5”

5.6”

636

196985

3” Low Profile

3.5”

5.6”

1738

397985

4” Low Profile

4.5”

5.6”

636

196986

4” Low Profile

4.5”

5.6”

1738

397086

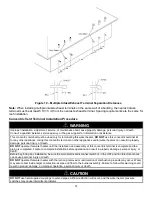

WARNING

When locating the penetration of the vent and air pipe, ensure the termination is properly oriented as shown

in Figure 26 and ensure that it maintains minimum clearance requirements as shown in Figure 25. For

multiple vent terminations, ensure that a minimum clearance of 12 in

(30 cm)

is maintained between edge of

air inlet and adjacent vent outlet and that all vent pipes and air inlets terminate at the same height to avoid

the recirculation of flue gases and the possibility of causing severe personal injury, death, or substantial

property damage (see Figure 28).

Installation Procedure

1. Once the proper location has been determined, cut 2 holes in the wall large enough to accommodate

the pipe. Pipe diameters and distance between hole centers can be found in Table 5.

2. Slide both the intake and vent pipe through the holes. Solvent weld both pipes to the base of the vent

termination kit (see Figure 25).

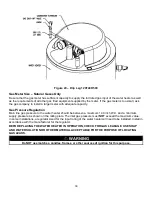

3. To fasten the base to the wall, use the supplied screws and anchors. A 3/16 in

(5 mm)

diameter, 1/16-

3/16 in

(2-5 mm)

deep hole will need to be drilled for the anchors. Locate the anchor hole by using the

base as a template and then drill the required holes.

4. Screw the cap to the base using the supplied screws.

5. Once the vent termination and pipes are secured, the wall penetrations will need to be sealed from the

interior using a PVC compatible material.

CAUTION

When installing the vent termination in a vertical configuration, ensure the vent piping is located above the

air inlet piping. This will avoid the risk of flue gas products recirculating into the air inlet and building.

Summary of Contents for LUHE120T

Page 42: ...42 BMS Wiring Diagram...

Page 44: ...44 Lighting and Shutdown Instructions Figure 31 Lighting Instruction Label...

Page 62: ......

Page 63: ......