Page 74

Maintenance procedures [Every 6 Months]

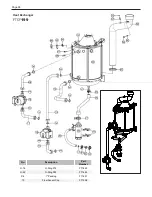

- Check the boiler piping (gas and water)

Visually inspect for leaks around internal water

piping. Also inspect external water piping,

circulators, relief valve and fittings. Immediately

call a qualified service technician to repair any

leaks. Leaks must be fixed by a qualified service

technician immediately.

Failure to comply with this instruction could result in

severe personal injury, death or substantial property

damage.

- Check the pressure relief valve

WARNING

Leaks must be fixed by a qualified service technician

immediately. Failure to comply with this instruction

could result in severe personal injury, death or

substantial property damage. This discharge line

must be installed by a qualified heating installer or a

service technician.

Before proceeding, verify that relief valve outlet has

been piped to a safe place of discharge, avoiding

any possibility of scalding from hot water. If water

flows freely, release the lever and allow the valve

to seat. Watch the end of the relief valve discharge

pipe to ensure that the valve does not weep after

the line has had time to drain. If the valve weeps, lift

the seat again to attempt to clean the valve seat. If

the valve continues to weep, contact your qualified

service technician for inspecting the valve and

system. If water does not flow from the valve even

though you have lifted the lever completely, the valve

or discharge line may be blocked. Shut down the

Combination boiler immediately. Call your qualified

service technician to inspect the combination boiler

and system.

- Check the burner state

You can clean the exterior of burner. However, if you

need to clean the inside of the burner stage, you should

call a qualified service technician.

A

A

FTCF 140

FTCF 199

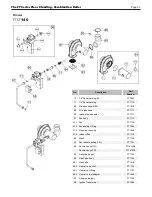

- Check the air vent

If the air vent valve seems to work freely without

leaking, replace cap “A” by twisting all the way on.

Loosen cap “A” one turn to allow vent to operate.

If vent does not operate correctly, replace the vent.