P 4.1

SECTION IV

Adjustments

A. ADJUST BRUSH TRACKING.

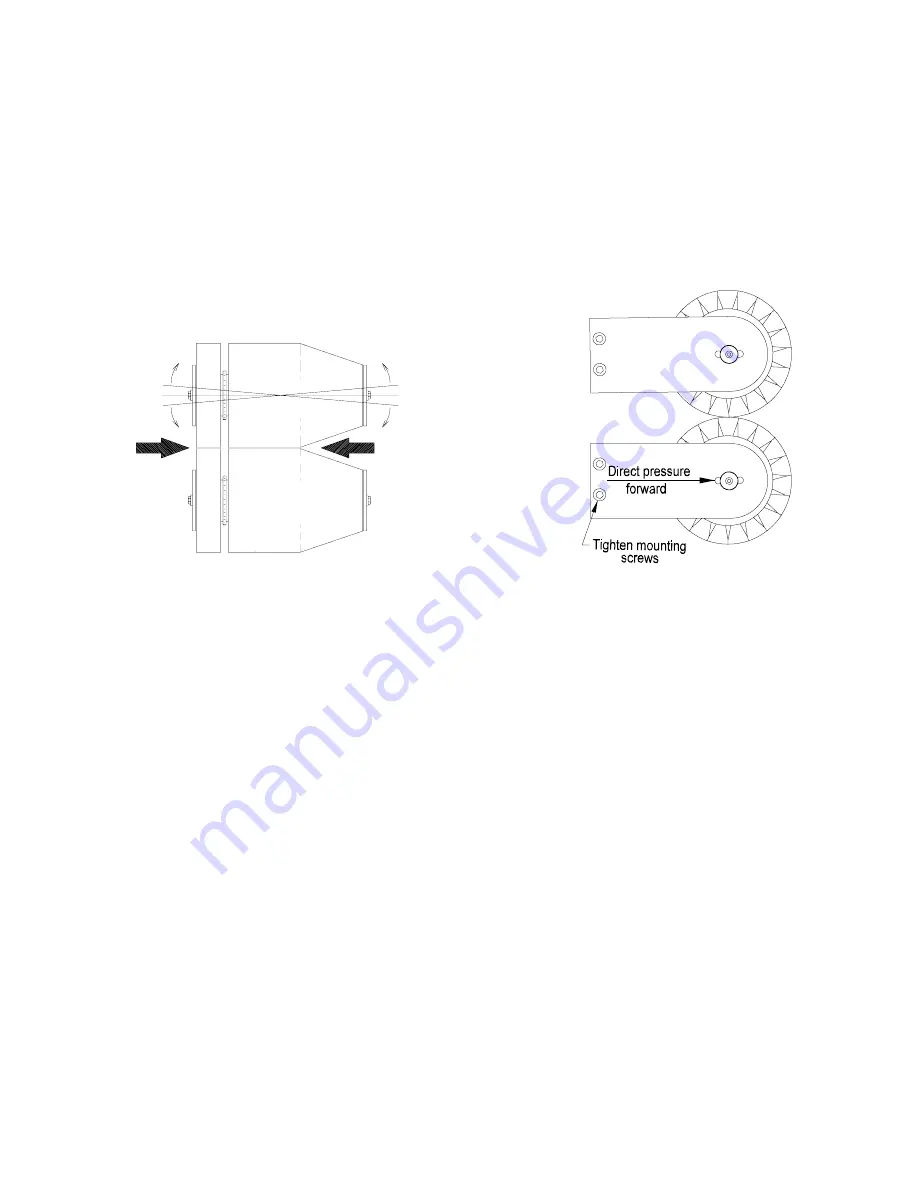

Figure 4.1 and 4.2

The bagneck should be as flat and wrinkle free as

possible as it enters the closer. The two brush assem-

blies should be parallel where they contact to optimize

the tensioners ability to prepare the bagneck for entry

into the closer. (Figure 4.1) The brush mount plates

mount with two 10-24 x 1/2" socket head cap screws.

These screws are used to align the brushes as follows.

1.

Loosen the two plate mounting screws on the

side of the brush assembly to be aligned.

2.

Hold the brush mount plate in your hand.

3.

Apply pressure to the back of the plate (opposite

the curved end) in a forward direction toward the

brush assembly (Figure 4.2).

4.

Raise or lower until the brush mount plate is

pressed firmly against both mounting screws.

(The mounting holes are oversized allowing for

this adjustment) Tighten the mounting screws.

5.

From the front of the tensioner check the gap

between the two brush assemblies and verify

that they are now parallel (this does not apply

to the tapered portion of brush assembly).

6.

If needed, repeat the adjustment.

CAUTION: DISCONNECT POWER TO THE

BAG TENSIONER BEFORE CONDUCTIONG

ADJUSTMENTS.

J8S 06 04

Figure 4.1

Figure 4.2