11

Section

3.2

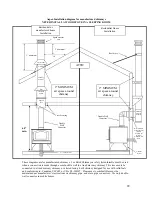

– Factory Built Fireplace installation

The fireplace must not be altered, except for the exceptions listed below. A permanent metal warning label

must be attached to the back of the fireplace, stating that the fireplace may have been altered to

accommodate the insert, and must be returned to original condition for use as a conventional fireplace. The

following modifications are permissible: removal of damper, removal of smoke shelf or baffle, removal of

ember catches, removal of fire grates, removal of viewing screen/curtain, and removal of doors.

The factory built chimney must be listed per UL 127 (US), and meet type HT requirements of UL 103

(US). Factory built fireplace chimneys tested to UL 127-1998, may be at the fireplace manufacturer’s

option, tested to the same criteria as UL 103 HT requirements. If the chimney is not listed as meeting HT

requirements, or if the factory built fireplace was tested prior to 1998, a full height listed chimney liner

must be installed from the appliance flue collar to the chimney top. The liner must meet type HT

requirements (2100 F) per UL 1777 (US). The liner must be securely attached to the insert flue collar and

the chimney top. To prevent room air passage to the chimney cavity of the fireplace, seal the damper area

with high temperature sealant.

The Kuma model Aspen is certified for installation into a properly installed factory built fireplace in the

U.S. A Safety listed 6” fireplace liner must be installed and directly connected to the appliance and must

extend to the original factory built chimney cap

Prior to installation:

1.

The following items may be removed in order to facilitate the liner installation: Smoke

Shelf/Baffle, Wood Grate, Viewing Screen, Damper, and ember catches.

2.

The Fireplace itself must not be altered (with the exception of damper removal). Any non-

functioning trims that are removed must be kept so that the fireplace can be restored to full

working order if the insert is ever removed.

3.

The local building department has the final authority to approve, with a permit, the installation of

this appliance into a factory built fireplace. DO NOT INSTALL WITHOUT A PERMIT.

4.

Check for any gap existing between the masonry fireplace construction and the fascia masonry. If

there is a gap, seal with a high temperature masonry mortar.

5.

The installation of the fireplace liner must in no way limit the airflow of the factory built chimney.

6.

The original factory built chimney cap must be reinstalled after the installation of the liner.

Notes on manufactured homes and fireplaces:

1. If you are installing the Aspen into a manufactured home, the fireplace must be manufactured

home approved with outside air capabilities.

2.

The outside combustion air that is fueling the fireplace must be supplied to the air intake on the

back of the Aspen stove. Where the outside combustion air enters the fireplace will most likely

vary depending on the particular fireplace. You will need to make sure that the air entering the

fireplace will not be blocked by setting the unit into place.

3.

All of the above guidelines in this section must be followed.

Guidelines for installation:

Use only pre-fabricated, listed components. Use of field fabricated components and/or using

“makeshift” compromises could result in a house fire.

1.

Secure the damper in the open position.

2.

This fireplace insert must be installed with a continuous chimney liner of 6” extending from the

fireplace insert to the top of the chimney. The chimney liner must conform to the class 3