Page 10

MAINTENANCE INSTRUCTIONS

Specific features have been designed into this stove which will simplify the required daily, weekly, monthly

and annual maintenance procedures. The frequency at which these must be performed depend upon

quality of fuel burned and fuel rate.

DAILY MAINTENANCE

The following procedures allow you to perform

daily maintenance on this stove without

interrupting the fire.

1. CLINKER REMOVAL (CORN USAGE)

After approximately 8 hours of stove operation, a

clinker will form and should be removed from the

burn pot. Waiting longer than 8 hours may result

in the clinker becoming calcified and hard,

making it difficult to remove from the burn pot.

NOTE: Using 100% corn burns cleaner than wood

pellets, however it will calcify after several hours of

burning. One method to prevent or minimize this

is to add wood pellets. The amount added is very

dependent on the type and quality of corn you

are using.

TO REMOVE THE CLINKER:

1. Press the heat setting level to #1.

2. Let stove burn at heat setting level #1 for

approximately 5 minutes.

3. Locate the two handles located directly under

the hearth extension. Refer to page 1.

4. While holding the left handle in place, pull the

right handle out approximately 3/4" and turn

the handle down, counter-clockwise to ‘drop’

one-half of the clinker.

5. Return the right ash drop pan to its original

position.

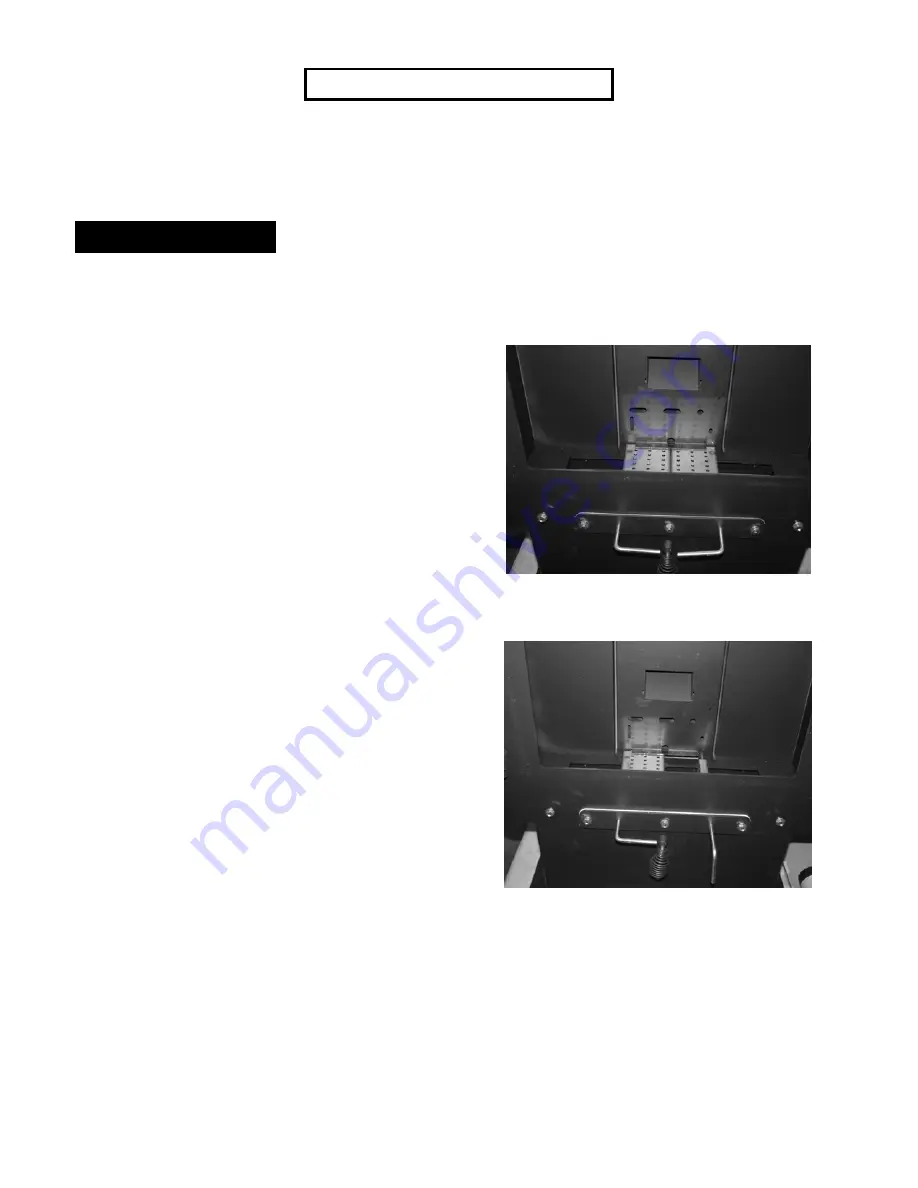

NOTE: The stove in the figures shown below has had several

components removed in order to provide you with a clear

understanding how the ash drop system operates.

It is not necessary to remove any component from this

stove or open the door to ‘drop’ the clinker into the ash

drawer.

Ash drop system shown in closed and secured system.

Ash drop system with right drop pan open.

6. Allow stove to burn for approximately 15 minutes to allow fire to re-establish itself in the right side of the

burn pot.

7 While holding the right handle in place, pull the left handle out approximately 3/4" and turn the handle

down, clock-wise, to ‘drop’ the remaining half of the clinker.

8. Return the left ash drop pan to its original position.

9. Re-set heat setting to desired level.