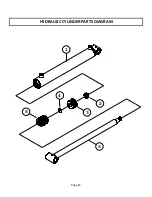

CYLINDER GLAND SERVICE DIAGRAM

CYLINDER PISTON SERVICE DIAGRAM

Page 17

To Install Seals:

1. Thoroughly clean piston sealing surface of all

foreign ma;er.

2. Heat new seals in hydraulic oil to 160

°

F.

Never use a direct flame or heated water on

hydraulic seals.

3. Remove seals from oil, wipe dry and install in

piston grooves as shown in illustra on at

leG.

Be sure seals have completely seated

in

piston grooves before allowed to cool.

4. Replace piston on cylinder shaG and

assemble

cylinder when seals have

cooled to room

temperature.

To remove seals

Carefully cut across each seal with a sharp knife. Be sure

not to scratch sealing surfaces of aluminum piston. If a

sharp knife is not available. An electric soldering gun or

hot iron may be used to melt throughout seals

All gland seals shown with a sec on removed

to facilitate correct installa on.

Note: To install rod wiper and EZ-squeeze seal,

fold similar to shape shown below, slip into

gland bore and locate each in its respec ve

groove. Tools are used to fold seals, take care

not to damage sealing surfaces.

Important! Be sure all gland and piston seals have been installed

correctly before cylinder is assembled!

O-RING

EZ SQUEEZE SEAL

ROD WIPER

BACK UP

GLAND

SECTION VIEW

ASSEMBLED GLAND

SECTION VIEW

ASSEMBLED PISTON

EZ SQUEEZE SEAL

PISTON

EZ SQUEEZE SEAL

O-RING

ROD WIPER

BACK UP

GLAND

EZ SQUEEZE SEAL

O-RING

O-RING

EZ SQUEEZE SEAL

PISTON

EZ SQUEEZE SEAL