Chapter 4 Troubleshooting

4-4

■

Troubleshooting Network Hardware

●

LED Status Indicator

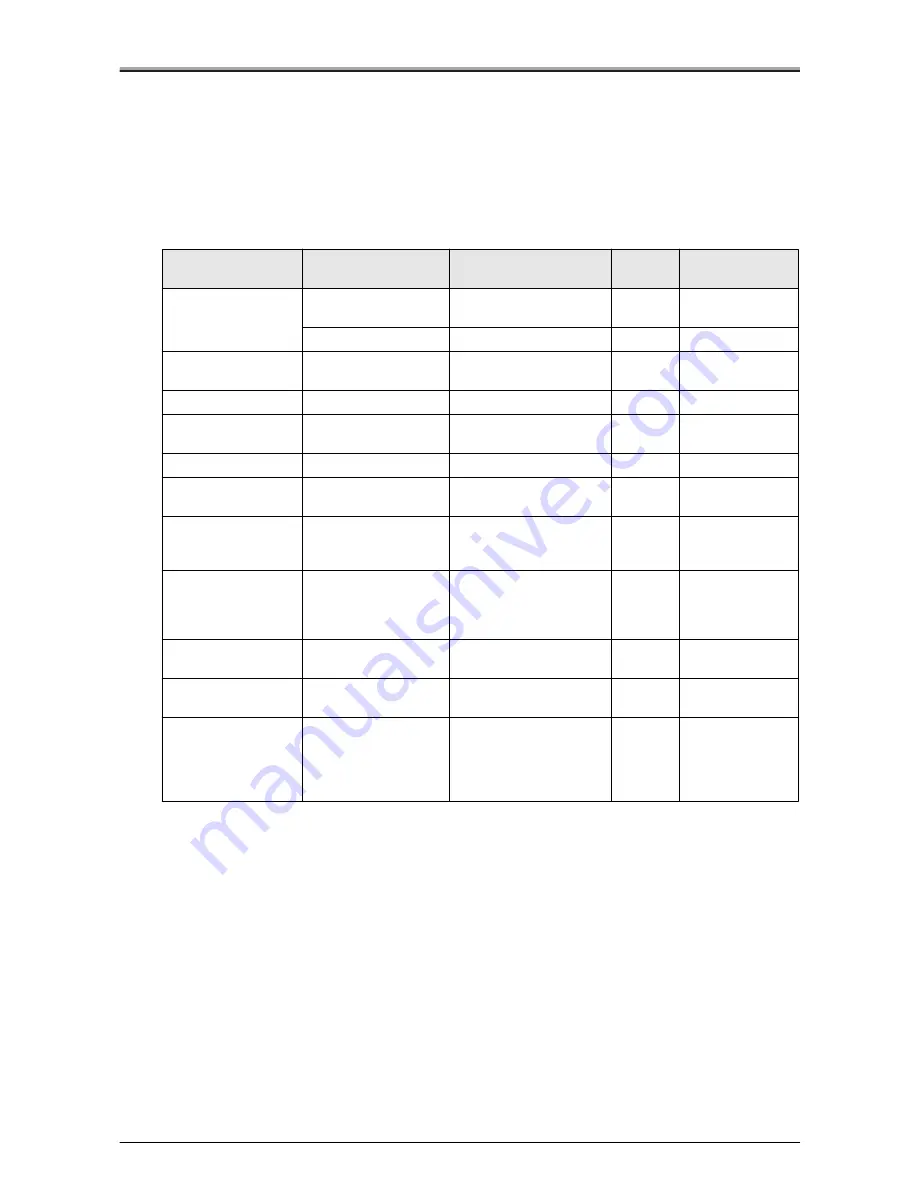

The network controller has two LED status indicators: amber and green. The amber LED generally indicates

job activity; it flashes when a print job is being communicated to the Network Controller; it is off when no

activity is occurring.

The green LED indicates the operating condition of the network controller when it is powered on during nor-

mal operation. The following table provides the conditions that these LEDs indicate.

LED status

Printer status

Network controller status

Operating

status

Action

Green lit

Immediately after main

power switched ON

Self-diagnostics executing

Normal

None

Waiting print job

Normal operation

Normal

None

Green LED flashes

three times

→

Lights up

Self-diagnostics com-

pleted

Network setting list print

Normal

None

Amber flashing

Waiting print job

Receiving print job

Normal

None

Amber lit up

Print job waiting/process-

ing

Normal operation

Normal

None

Amber off

Waiting print job

No print jobs

Normal

None

Green flashing rapidly

Self-diagnostics execut-

ing

RAM chip defect detected

Error

Replace the system

board

Green LED flashes four

times rapidly

→

Goes

out

Self-diagnostics execut-

ing

Ethernet hardware self-diag-

nostics failure

Error

Check the network

again

Amber LED flashes

about 10 seconds

→

Goes out

→

Green LED

continues flashing

Flash memory self-diag-

nostics executing

Did not pass the check-sum

test

Error

Execute flash

update

Green LED flashing

slowly

Power on completed,

then print job waiting

Printer interface error

Error

Replace the system

board

Green LED flashing rap-

idly

Print job waiting

NetWare connection to file

server not possible

Error

Check NetWare set-

tings

Green LED alternately

blinks with amber indi-

cator

Finished power-on

sequence

Has been reset to factory

defaults

Error

Reset the settings

as described in

"Resetting the net-

work controller to

Factory Default".

Summary of Contents for IP-422

Page 2: ......

Page 3: ...IP 422 IP 423 SERVICE MANUAL OCTOBER 2002...

Page 16: ...SAFETY AND IMPORTANT WARNING ITEMS S 10...

Page 17: ...Overview 1...

Page 18: ...Blank Page...

Page 26: ...Chapter 1 Overview 1 8...

Page 27: ...Disassembly Reassembly 2...

Page 28: ...Blank Page...

Page 41: ...Field Service 3...

Page 42: ...Blank Page...

Page 65: ...Troubleshooting 4...

Page 66: ...Blank Page...

Page 77: ...Appendix...

Page 78: ...Blank Page...

Page 88: ...Appendix Appendix 10 MEMO...