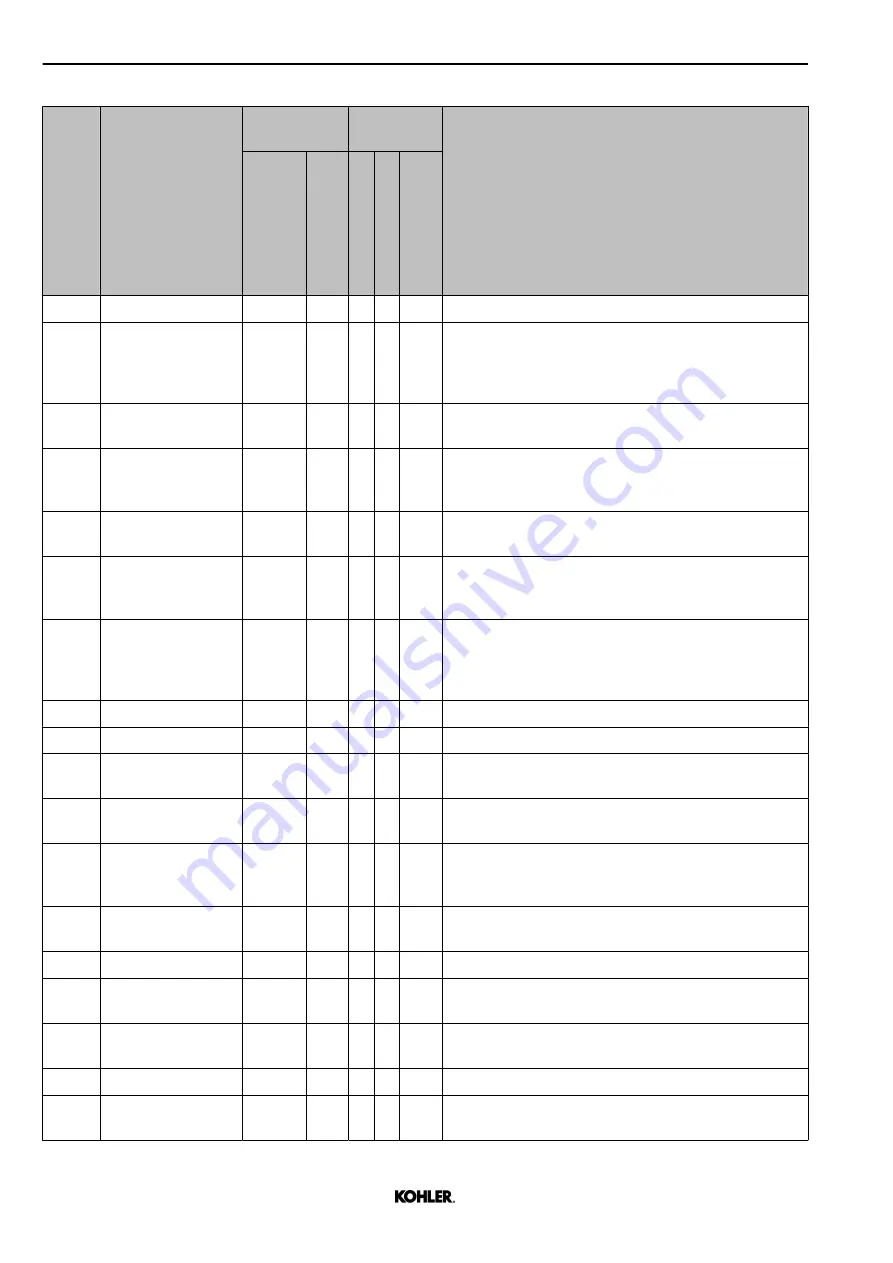

Maintenance

Inspection and maintenance schedules

Task iden

tification

Component

Schedule

Service

Type

Task description

Time limit (h)

Calendar limit (y

ear)

R

eplacemen

t

Ov

erhaul

Inspection/Clean R

epair

/Adjus

tmen

t

SL205

Fuel injectors

7500

8Y

X

Replace.

SL206 Combustion cham‐

bers

7500

8Y

X

Done at the time the injectors are replaced. Use a

borescope to identify condition of combustion

chamber (piston crown, liner hatches, fire deck,

etc.).

SL2-13

40

Torsional vibration

damper

4000

X

Replace.

SL2-13

45

Silicon oil of

torsional vibration

damper

1000

1Y

X

Collect and send silicon oil sample for analysis.

SL209 HP fuel pump and

LP fuel pump

-

8Y

X

Inspect for leaks. Replace pump if necessary.

SL212

Cold start oil

cooler by-pass

valve

7500

18Y X

Replace.

SL213 Exhaust gas turbo‐

chargers

7500

18Y X

Check overall condition (compressor blades, leaks,

connections, housings, etc.) every 4000 hours.

Replace the exhaust gas turbocharger at the indi‐

cated service interval.

SL215

LT coolant pump

7500

18Y X

Replace.

SL216

HT coolant pump

7500

18Y X

Replace.

SL217

Coolant thermo‐

stats

7500

18Y X

Replace.

SL218 Auxiliary belt drive

- PTO

7500

18Y X

Replace.

SL219

Rubber sleeves

7500

18Y X

Replace all rubber hose connections on the engine:

e.g., coolant hoses for ECU cooling, hose connec‐

tions for crankcase ventilation.

SL220

Charge air cooler

7500

18Y

X

Check visually for leaks. If shown, identify reason.

Replace component if needed.

SL221

Oil cooler

7500

18Y

X

Inspect the oil cooler.

SL222

Recommended:

Starter

7500

18Y

X

Inspect the starter (winding insulation, relay, condi‐

tion of the gear teeth, etc.).

SL223

Battery charging

alternator

7500

18Y X

Replace.

SL224

Cylinder heads

7500

18Y X X

Replace.

SL2-53

30

Diesel exhaust

fluid injectors

5000

-

X

Replace.

92

© 2022 by Kohler Co. All rights reserved.

KD62V12 33521030301_8_1 EN_US 2022-09