TP-6069 6/03

70

Section 8 Reconnection/Adjustments

Short circuits.

Hazardous voltage/current can cause

severe injury or death.

Short circuits can cause bodily injury

and/or equipment damage

.

Do not contact electrical

connections with tools or jewelry while making adjustments or

repairs. Remove all jewelry before servicing the equipment.

Overvoltage Shutdown Adjustment Procedure

1. Disconnect the generator set engine starting

battery, negative (--) lead first. Disconnect power to

the battery charger (if equipped).

2. With the generator set shut down, open the output

line circuit breaker to disconnect the load from the

generator set.

3. Remove the controller cover.

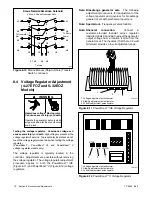

4. Wrap the shaft of an insulated-handle screwdriver

with electrical tape to insulate the metal shaft. Turn

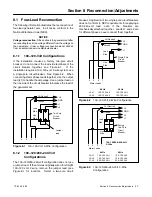

the overvoltage potentiometer (R41) on the main

circuit board fully clockwise. See Figure 8-8.

5. Connect a digital AC voltmeter (or other 1%

minimum accuracy voltmeter) to terminals V0 and

V7 on the controller terminal block.

See

Figure 8-6.

6. Reconnect the battery, negative (--) lead last.

7. Start the generator set by placing the generator set

master switch in the RUN position.

8. Adjust the output voltage to 115% of the nominal

output voltage using the voltage adjustment

potentiometer.

If the voltage configuration is

139/240 volts (low wye) or 277/480 volts (high

wye), 3-phase, 4-wire, 60 Hz, adjust output voltage

to 160 volts across terminals V0 and V7. For all

other voltages, adjust the output to 140 volts

across terminals V0 and V7.

Adjust the voltage using the voltage adjustment

potentiometer on the generator controller front

panel. See Figure 8-7.

9. Use the insulated screwdriver to slowly rotate the

overvoltage

adjustment

potentiometer

(R41)

counterclockwise until red LED4 lights.

See

Figure 8-8. The generator set should shut down on

an overvoltage fault in approximately 2 seconds.

P1

P2

A-336415-A

2

R41

LED4

1. Overvoltage adjustment potentiometer (R41)

2. LED4 (red)

1

Figure 8-8

Overvoltage Shutdown Adjustment on

Main Circuit Board

10. Turn

the

voltage

adjustment

potentiometer

counterclockwise to prevent overvoltage shutdown

upon restart. Restart the generator set. Slowly

increase the voltage by turning the voltage

adjustment potentiometer clockwise.

Verify the

shutdown voltage point (115% of the nominal

output voltage) by observing the voltmeter and

noting when LED4 lights. The generator set should

shut down on overvoltage fault in approximately

2 seconds. If the shutdown voltage point is not

115% of nominal voltage, repeat the calibration

output procedure; otherwise, continue to step 11.

11. Turn

the

voltage

adjustment

potentiometer

counterclockwise to prevent overvoltage shutdown

upon restart. Restart the generator set. Readjust

the generator set output to the nominal voltage

using the voltage adjustment potentiometer.

12. Stop the generator set by placing the generator set

master switch in the OFF/RESET position. Seal

the overvoltage adjustment potentiometer (R41)

with RTV sealant or equivalent.

Replace the

controller cover.

Summary of Contents for 100EFOZ

Page 2: ......

Page 4: ......

Page 10: ...TP 6069 6 03 VI Safety Precautions and Instructions Notes ...

Page 12: ...TP 6069 6 03 2 Section 1 Introduction Notes ...

Page 14: ...TP 6069 6 03 4 Section 2 Location and Mounting Notes ...

Page 20: ...TP 6069 6 03 10 Section 3 Cooling System Notes ...

Page 26: ...TP 6069 6 03 16 Section 4 Exhaust System Notes ...

Page 38: ...TP 6069 6 03 28 Section 6 Electrical System Notes ...

Page 84: ...TP 6069 6 03 74 Section 8 Reconnection Adjustments Notes ...

Page 89: ......

Page 90: ......

Page 91: ......