TP-6069 6/03

24

Section 6 Electrical System

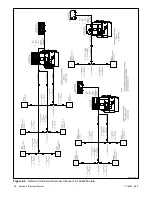

6.5 Battery

Batteries and their installation must conform to USCG

Regulations 183.420 (a) through (g). Provide generator

sets with batteries separate from the propulsion

engine’s whenever possible.

The starting/charging

systems of both the generator set and the engine must

have a common negative (--) ground.

USCG

Regulation

183.415,

Grounding,

requires

connection of a common conductor to each grounded

cranking-motor circuit. Size the conductor to match the

larger of the engine’s two battery cables. Figure 6-5 lists

cable sizes for generator set battery connections at

various ambient temperatures. Connecting a common

conductor to each grounded cranking motor circuit

prevents the starting motor current from using

alternative electrical paths should the cranking motor

ground circuit be restricted or open because of oxidation

or loose hardware. Alternative electrical paths include

metallic fuel lines that can pose a fire hazard. See

Figure 6-7 and Section 7 for battery connections to the

generator set.

Distance between

Cable Size (AWG)

Distance between

Generator Set

and Battery m (ft.)

At –18

°

C

(0

°

F)

At 0

°

C

(32

°

F)

At 24

°

C

(75

°

F)

12.2

(40)

00

0

1

9.1

(30)

0

1

2

7.6

(25)

1

2

4

6.1

(20)

2

2

6

4.6

(15)

2

4

6

3.0

(10)

4

6

8

1.5

(5)

6

6

8

0.8

(2.5)

8

8

8

Figure 6-5

Battery Cable Sizes

Kohler Co. recommends using one 12-volt or 24-volt

battery (as the spec requires) to start the generator. See

Figure 6-6 for minimum cold cranking amps (CCA)

recommendations.

12-Volt Starting Battery Size CCA

at --18

°

C (0

°

F) or 100 Amp. Hr.

Models

CCA

3.5–20EFOZ and

4--24EOZ

500

23/27/100/125EFOZ and

28/32/125/150EOZ

800

33--80EFOZ and

40--99EOZ

640

Figure 6-6

Battery Recommendations

1

3

2

4

5

TP-5586-6

1. Starter solenoid

2. Battery positive (+) connection

3. Equipment ground

4. Battery negative (--) connection

5. Engine block mount

Figure 6-7

Battery Connections (5EOZ/4EFOZ

model shown)

6.6 Wiring

Use only stranded copper wire.

Conform to USCG

Regulations 183.425 through 183.460 for wire gauges

and insulation, conductor temperature ratings, sheath

stripping, conductor support and protection, conductor

terminals and splices, and over-current protection

(circuit breakers, fuses). Use rubber grommets and

cable ties as necessary to protect and secure the wire

from sharp objects, the exhaust system, and moving

parts.

Summary of Contents for 100EFOZ

Page 2: ......

Page 4: ......

Page 10: ...TP 6069 6 03 VI Safety Precautions and Instructions Notes ...

Page 12: ...TP 6069 6 03 2 Section 1 Introduction Notes ...

Page 14: ...TP 6069 6 03 4 Section 2 Location and Mounting Notes ...

Page 20: ...TP 6069 6 03 10 Section 3 Cooling System Notes ...

Page 26: ...TP 6069 6 03 16 Section 4 Exhaust System Notes ...

Page 38: ...TP 6069 6 03 28 Section 6 Electrical System Notes ...

Page 84: ...TP 6069 6 03 74 Section 8 Reconnection Adjustments Notes ...

Page 89: ......

Page 90: ......

Page 91: ......