φ32

φ32

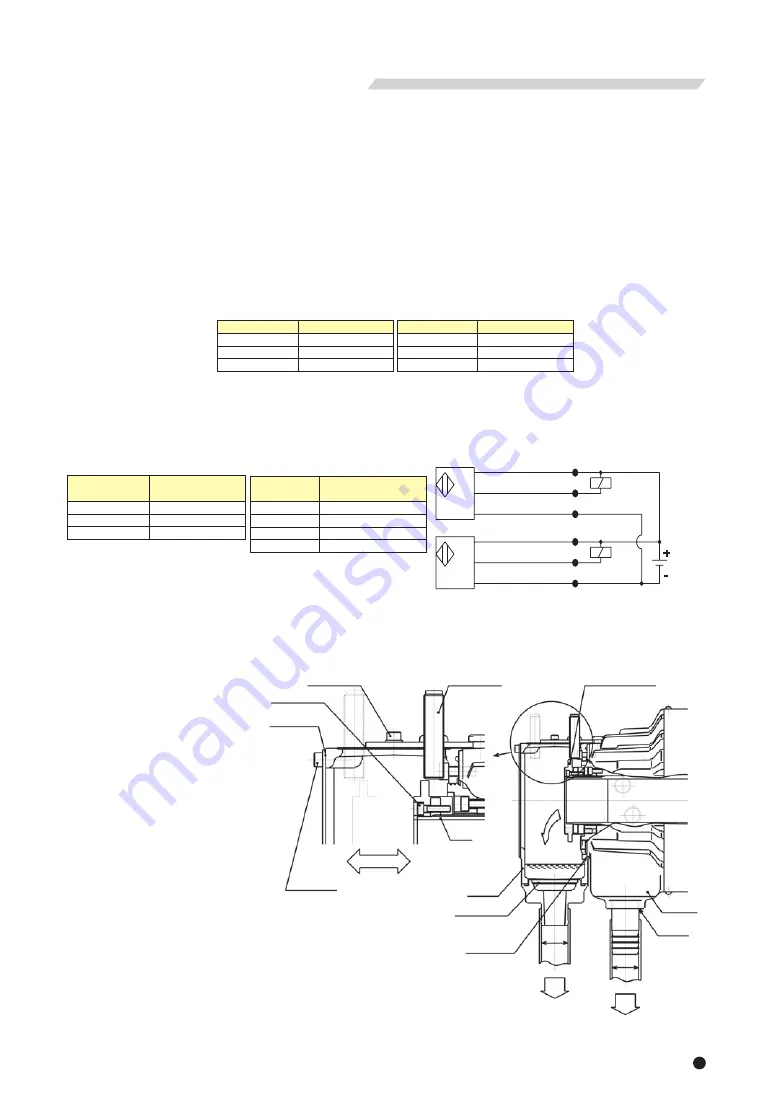

Socket head

cap screw[15]

Washer[18]

Cover[3]

Proximity switch[22]

Seat packing[8]

Lock bolt

Socket head cap screw[14]

Forward

Back

Stroke

Chuck close

(O.D. gripping)

Socket head cap screw[15]

Chuck open

(O.D. gripping)

Plston

Detectable Plate[11]

After securely tightening to the

piston.tighten the lock bolt

Coolant

Always clean so that the

chips are not clogged

Body[1]

Sheet packing[7]

Metal screen[6]

Sleeve body

Drain port

To the tank

for coolant

To the

hydraulic unit

DC24V

BK(Out put) OP2

BK(Out put) OP1

Type

Applicable cylinder

CSS10BN

CSS12BN

CSS15BN

S1036

S1246, S1246L

S1552, S1552L

Type

Applicable cylinder

CSS18BN

CSS20BN

CS-28SW

S1875, S1875L

S2091, S2091L

S2816

Type

BES M12MI-NSC20B-BV02

(BALLUFF)

Voltage

Leakage current

Operation style

24V DC

200mA or less

NPN

Type

BES M12MI-NSC20B-BV02

(BALLUFF)

OP2

+V

0V

OP1

BLACK

BROWN

BLUE

BLACK

BN(+) +V

Load

Load

BU(−) 0V

BN(+) +V

BU(−) 0V

17

18

Check the points specified below again and take measures.

7−1 In the case of malfunction

In the case of malfunction, contact the distributor where you purchased the product or our branch office listed on the

back cover.

7−2 Where to contact in the case of malfunction

7 . Malfunction and Countermeasures

○The coolant collector is attached to the Kitagawa S type rotation hydraulic cylinder, and easily collects the coolant

flowing inside the draw pipe.

○To electrically check piston operation and for clamping/unclamping detection of a work, There are 2 proximity

switches attached to the coolant collector.

○The coolant collector is to be arranged separately from the cylinder, so designate the type specified below when

necessary.

○There are 2 proximity switches attached on the coolant collector, therefore, the cylinder operation can be checked.

8−1 Outline

8 . Coolant Collector

・If the chuck failed due to a seizure or breakage, remove the chuck from the machine, following the disassembly

steps in the chuck instruction manual, and then remove the cylinder by the reverse steps of "9. Attachment" after

page 21. When the jaws and covers cannot be removed due to a blockage of workpiece, do not disassemble

forcibly but please contact us or our agent.

・If these countermeasures do not correct the problem or improve the situation. Immediately stop using the

machine. Continuous use of a broken product or a defective product may cause a serious accident by the

cylinder or the work flying out.

・Only experienced and trained personnel should do repairs and fix malfunctions. Repair of a malfunction by a

person who has never received instruction from an experienced person, the distributor or our company may

cause a serious accident.

Table 4

8−2 Type and applicable cylinder

○The standard specification of the proximity switch is BES M12MI-NSC20B-BV02 (BALLUFF). Contact us if a

specification other than the standard one is necessary.

8−3 Specifications

○Insert a sheet packing between

the coolant collector main body

and the sleeve body at the

cylinder rear end, and attach

the coolant collector to the

cylinder rear end.

○After attaching the coolant

collector, attach the detectable

plate to the piston.

○To easily collect the coolant

flowing into the coolant

collector, provide appropriate

slope to the piping, so that the

coolant does not stagnate

inside the hose.

To check the flow, use a

transparent vinyl hose.

(Inside diameter φ32) (Fig. 6)

8−4 Attachment

Fig. 5

Table 5

Table 6

Table 7

Fig. 6

WARNING

Defective

Measures

Check that the hydraulic pressure is operating by the motion of the flexible hose, etc.

Check that there are no mistakes in piping.

Try operations when operation inability specified in the items of the trial operation.

Check that the pressure is as specified at the cylinder pipe inlet by attaching a pressure

gauge near the inlet of the cylinder.

Wearing of the O-ring inside is possible when the flow rate of the returning side pipe or

the drain is more than usual.

Check that the viscosity of the hydraulic oil is as designated.

Replenish the hydraulic oil inside the tank if it is low.

When the room temperature is high and the radiation effect of the tank is bad, control

the oil temperature using a cooler or a fan, etc.

Do not suck air.

Replenish the hydraulic oil inside the tank if it is low.

If a large amount of dirt is deposited inside the tank, or when the hydraulic oil is

deteriorated, the pump may be worn out abnormally, and it will be necessary to repair

the pump.

Provide a stream slope, without air pockets, and no back pressure must be applied.

Return the drainage onto the surface of the oil of the hydraulic unit .

Check that the air breather of the hydraulic unit is not clogged.

Piston

Operation

Inability

Cylinder

Thrust Force

Insufficiency

Temperature

Rise

Pump noise

Oil leakage

from labyrinth

Summary of Contents for S1036

Page 31: ......