A

Caring for Connectors

76

Keysight N4000/1/2A Operating and Service Manual

Hold the torque wrench lightly by the knurled end of the handle only. Apply force

at the end of the torque wrench only, perpendicular to the wrench and always in a

plane parallel to the outer conductor mating planes. This will result in torque

being applied to the connection through the wrench until the break point of the

wrench is reached.

Avoid pivoting the wrench handle on the thumb or other fingers. This results in an

unknown amount of torque being applied to the connection when the break point

of the wrench is reached. Avoid twisting the head of the wrench relative to the

outer conductor mating plane. This results in applying more than the

recommended torque.

To reiterate the main do’s and do not’s detailed previously:

– Avoid holding the wrench tightly, in such a way that the handle is not pivoted

but simply pushed downward the same amount throughout its length. If this is

done, an unlimited amount of torque can be applied.

– Hold the wrench at the same point near the end of the handle every time, and

always in the same orientation. Whenever possible, begin tightening the

connection with the wrench held horizontally.

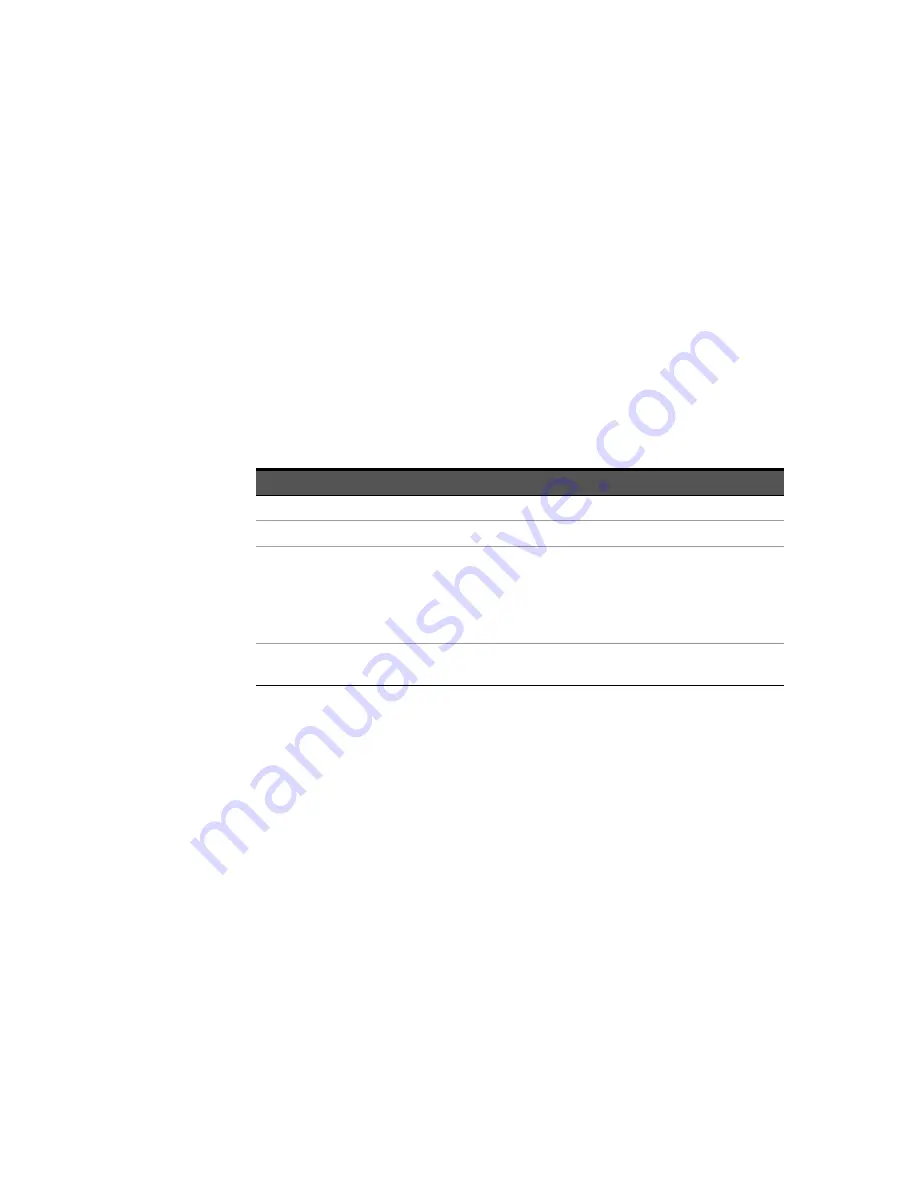

Table A-2

Recommended torque settings

Type

Description

Precision 7 mm

12 lb-in (136 N-cm)

Precision 3.5 mm

8 lb-in (90 N-cm)

SMA

5 lb-in (56 N-cm)

Use the SMA wrench to connect male SMA connectors to female precision

3.5 mm connectors.

Connections of male precision 3.5 mm connectors to female SMA connectors

can be made with the precision 3.5 mm torque wrench (8 lb-in).

Type-N

Type-N connectors may be connected finger tight. If a torque wrench is used,

12 lb-in (136 N-cm) is recommended.